Operating manual for automatic line brand nnx1200 for welding H-shaped beams. Feeding line atesy® user manual nm.01.000.000re rev.01 Feeding line thank you for purchasing our line

automatic line grade ННХ1200 for H-beam welding

HNH1200 automatic line for H-shaped beam welding is used for the production of steel I-beam (H-profile steel). The line allows you to continuously perform product assembly, welding, straightening and exit finished products. The line is equipped with a programmable control unit (PLC) and a frequency-converting speed controller.

I. Line device

1. Main machine

2. Power supply system.

3. Assembly mechanism.

4. Supporting device No. 1.

5. Unloading device (including supporting device No. 2).

6. Hydraulic system.

7. Alignment device

8. Wire feeder.

9. Working platform and ladder.

10. Power supply: two DC submerged arc welding machines manufactured by Lincoln, USA.

11. Flux return device, two pcs.

II. Regulations Maintenance

1. Preparation of equipment for work.

1.1 Check the status of the connections, turn on the toggle switch and press the main power button.

1.2 Press the main power button, adjust the height of the moving beam according to the parameters of the product.

1.3 On the assembly mechanism, adjust the height of the clamping roller for the I-beam wall.

1.4 Adjust converter frequency according to welding speed.

1.5 Adjust the pressure force of the straightening rollers and the distance between two straightening rollers according to the parameters of the product.

1.6 Adjust the working pressure of the driving cylinder, the assembly cylinder and the wire (solder) feeding cylinder on the driving beam.

1.7 Adjust the electrical voltage, electrical current and welding speed according to the parameters of the product.

1.8 Release the button and turn on the electric motor of the pumping system.

2. Preparation of the welding system:

2.1 Set up the welding machine according to the instructions.

(1) Set the remote control(Out Control Remote) and the remote control(Out Control at DC-1000)to remote control first.

(2) The modular system switch is divided into the following positions: CV(I), CV (S) and CC (refer to manual for description of different modular systems). Usually set to the position of the SS system.

(3) For a DC welding machine, cable connections must be made according to the requirements of this type of welding. In case of counter-inclusion, connect the burner to the positive electrode, and the product to the negative one. Polarity set to “ + ”, in the opposite - “ - ”.

(4) After making the above adjustments, press the “Start” button and turn on the power.

2.2 Turn on the toggle switch on the control panel.

2.3 Press the “Inch Down” button and insert the welding wire of the desired diameter into the torch. Set the length of the free end of the wire to the mouthpiece (ie the length of the protruding part of the wire) 20-30 mm. The “Inch Down” button is a wire return button.

2.4 To obtain good ignition, cut the free end of the wire at a sharp angle.

2.5 Check the settings of the ignition panels and the filling of the arc crater. Installing the ignition panel ensures a good ignition effect through the correct adjustment of the values of electric current, voltage and ignition time. Before the end welding work press the “Stop” button on the panel to fill the arc crater. Further pre-burning with welding wire will give a good final weld. You can pre-set the values of electric current, voltage and filling time of the arc crater.

2.6 Adjust the angle between the torch and the level to the desired welding angle. The recommended angle (between the burner and the I-beam flange) of the burner is 30-50 degrees.

2.7 Adjust the distance between the two burners. The distance between two burners should be about 200 mm.

2.8 Turn on the tube toggle switch for flux supply.

2.9 Turn on the flux return device; suck some of the flux into the trap and set the trap head correctly.

3. The procedure for carrying out welding work

3.1 Place the I-beam blank in the central position on the assembly mechanism. Turn on the alignment cylinder, the piston of the cylinder will extend and the intake block will rise. When the cylinder for the I-beam flange is turned on, it is pulled out by the returning cylinder. If necessary, the dissolution of the wall of the I-beam, press the button.

3.2 Place the blank of the I-beam wall in the central position on the assembly mechanism and align the ends of the flange and the I-beam wall. Turn on the wall cylinder, while the cylinder will return back, through the rocking chair it will clamp the wall and evenly pull it out. If necessary, the dissolution of the wall of the I-beam, press the button. Turn on the cylinder for alignment, this will return the piston of the cylinder and raise the intake block.

3.3 The electric motor of the assembly mechanism is switched on with a delay of 3 seconds. Then press the “forward” button, and the electric motor will feed the product forward. When the free end of the product reaches the straightening machine, the center lines of the product and the machine (i.e. the center line of the drive roll of the straightening machine) must be reconnected. Under this condition, the central lines of the shelves, walls and drive straightener will be coaxial.

3.4 The left and right shelf mounting devices clamp both shelves and mount them on the center line.

3.5 The left (No. 1) and right (No. 2) side setting device clamps the product and installs the wall on the center line.

3.6 After centering, return the products under the pressure roller of the moving beam.

3.7 Adjust the location of the two large pressure rollers on the straightening machine according to the size of the I-beam shelves so that the distance between the ends of the pressure rollers and the center line (the center line of the drive roller of the straightening machine) becomes the same. Adjust the heights of the two large pressure rollers so that the rollers firmly compress the I-beam shelves with the same force.

3.8 Press the button and turn on the feed cylinder on the moving beam, while the cylinder rod protrudes downward, and the clamping roller slightly compresses the product to check the alignment of the center lines of the shelves, the I-beam wall and the main roller of the straightener. Press the button again, after which the clamping roller will strongly compress the workpiece.

3.9 When the free end of the product approaches the welding site, it is required to press the solder supply button, while the rod protrudes and moves the torch to the welding site. Set all the necessary adjustments on the panel of the welding control unit: set the desired values of current and voltage; then press the “Start” button. Both welding machines will start their work with the simultaneous activation of the flux trap.

3.10 During the welding process, if it is necessary to improve the quality of the weld, the burner can be readjusted at any time.

3.11 After straightening, the pressing stage begins. Based on the degree of deformation of the product, it is necessary to adjust the cylinder of the pick-up device and the cylinder of the load roller of the driven pick-up rack so that the two load rollers touch the deformed product. In this case, the product will successfully pass the extrusion process.

3.12 At the moment when the free end of the product moves away from the drive gear, the pushing cylinder on the driving beam returns. When the free end of the product moves away from the working torch, the welding machine extinguishes the arcs, while returning the torch to its original state.

3.13 At the moment when the free end of the product moves away from the straightening machine, it is required to turn off the electric motor of the main mechanism.

3.14 After that, the cylinder rods of the pick-up device and the load roller of the drive racking mechanism return, the pick-up roller descends, and the product is on the ejector knurlers.

3.15 Install another I-beam shelf blank into the assembly mechanism. Turn on the alignment cylinder, the piston of the cylinder will extend and the intake block will rise. Turn on the cylinder for the I-beam flange, while the cylinder returns and pulls the I-beam shelf through the handle. If necessary, the dissolution of the I-beam shelf, press the button.

3.16 Align the welded product of the brand with the center line of the second shelf. Align the ends of the shelf and brand products. Turn on the wall cylinder, while the cylinder returns back and clamps the wall through the rocking chair, evenly pulling it out. If necessary, the dissolution of the I-beam shelf, press the button. Turn on the cylinder for alignment, this will return the piston of the cylinder and raise the intake block.

3.17 Repeat the steps described in paragraphs 2.3 - 2.11.

3.18 Turn off the production line.

4. Notes

4.1 Before switching on, make sure that there are no foreign objects interfering with normal operation.

4.2 Check if the power and hydraulic system buttons have returned to their original position.

4.3 Start the operation of the line by turning on the power supply of the hydraulic pump.

4.4 When the pumps are de-energized or stopped, it is necessary to prevent the product from deviating from the set position due to a decrease in pressure from a long-term power outage.

4.5 During installation of the product, avoid collisions with the vertical shaft and rocker of the assembly mechanism.

4.6 Permissible deviation of the total curvature of the material of the welded product (table sheet) is less than 0.10%L.

4.7 In order to avoid malfunctions, it is necessary to frequently check the moving parts of the mechanisms, the joints of their parts and the electromechanical control system. Eliminate all detected malfunctions promptly and in a timely manner.

4.8 Before starting operation, adjust the tensioner and tension the chains.

4.9 The solder supply hose should be free to rise and fall on the side of the cylinder carriage. Twisting, bending and squeezing of the hose is not allowed.

4.10 Check the correct connections of the power supply and the control unit of the welding line. After installation, it is imperative to make sure that all parts and sections are isolated, avoiding current breakdowns.

4.11 Only a standard three-phase four-wire power supply system is allowed.

4.12 Before carrying out welding work, it is necessary to carefully check the insulation of the earth line in the electrical cabinet, system welding machine and other welding machines in the workshop. Increasing the voltage to 500 V, measure the resistance. It should not be lower than 1 kOhm. After checking and obtaining a satisfactory result, subsequent work can be carried out.

5. Service

| Item number | Mechanical | Period | The content of preventive work | Notes |

| 1 | mechanical unit | Every day | 1. Lubrication of rocking, fixation and orientation mechanisms. 2. Every day before switching on, check the condition of the connections of the mechanism; remove foreign objects at the end of work. 3. Check for oil leakage at the junctions of the hydraulic pipes. | Apply oil number 30 |

| 2 | Lifting mechanism, drive, and chain transmission mechanism | A week | 1. Grease the top roller. 2. Cleaning and lubrication of the chain and chain gear. 3. Cleaning and lubricating the guide rails and screws. 4. Tensioner adjustment, tension the chain. | Apply calcium grease No. 2. Apply oil number 30 |

| 3 | Reducer | 1. Regular lubrication. 2. Oil change every six months. | Apply oil number 40 |

|

| 4 | Supporting device and small pick-up device. | Month | Rotating parts. | Apply calcium grease No. 2 |

| 5 | Pumping system | A week | Check oil level, add if necessary. | Slurry No. 46 |

| half a year | 1. Regular cleaning. 2. Oil change every six months (pour the slurry into the tank only after filtering). | |||

| One and half year | Perform a hydraulic system overhaul. |

IV. Malfunctions and their elimination.

| 1. Indicator lamp does not light | 1) Check the main power switch and power management system. 2) Check the integrity of the fuse in the control unit. 3) Check the integrity of the indicator lamp. |

| 2. The roller table does not rotate. | 1) Check the start button and its connection to the power supply. 2) Check the power supply cable at the drive motor. 3) Check the operation of the gearbox and the condition of the coupling bolt. 4) Check the connection of the chain with the gear. |

| 3. The hydraulic cylinder does not move | 1) Check the state of rotation of the motor. 2) Check the oil level against the mark. |

V. Welding technology

| Caliber, mm | Solder diameter, mm | Welding current, A | Electric arc voltage, V | Welding speed, mm/min. |

| 4 | 3 | 350~370 | 28~30 | 880~910 |

| 6 | 3 | 450~470 | 28~30 | 900~960 |

| 4 | 480~500 | 28~30 | 960~1000 |

|

| 8 | 3 | 500~530 | 30~32 | 730~760 |

| 4 | 670~700 | 32~34 | 800~830 |

Note: The above values are for example only.

VI. Causes of defects in submerged arc welding and measures to eliminate them.

| Number | Defect | The main reason | Corrective action |

| 1 | Crack | 1) Mismatch between wire and solder. 2) Poor preparedness of the welded shelves and walls of the I-beam and their discrepancy technological characteristics to welding conditions. 3) Unsuitable joint cooling method. | 1) Choose a suitable combination of wire and solder. 2) Monitor the welding process. 3) After welding, carry out heat treatment. |

| 2 | cutout | 1) Welding speed too high. 2) The gap between the gasket and the product is too large. 3) The current and voltage do not match the welding conditions. 4) Offset location of wire and solder. | 1) Reduce welding speed. 2) Make the gasket and product fit. 3) Adjust welding current and arc voltage. 4) Adjust the location of the solder wire. |

| 3 | surfacing | 1) The welding current is too high. 2) The welding speed is too low. 3) Arc voltage too low. | 1) Reduce welding current. 2) Increase welding speed. 3) Increase the voltage. |

| 4 | Slag clogging | 1) Deviation of the product from the welding line and runoff of slag. 2) Corrugation is observed at the beginning of the seam (especially when there is an arc deflecting plate). 3) The welding current is too low; and in multi-layer welding, slag is difficult to remove. 4) Too low speed welding and slag runoff. | 1) Weld from the opposite side, or place the product in a horizontal position. 2) Lead in Thickness Compliance arc deflector plate and welding line. 3) Increase the current so that Slag from welding Completely melted away. 4) Increase current and welding speed. |

| 5 | Headroom is too big | 1) The welding current is too high. 3) The welding speed is too high. | 1) Reduce the current to an appropriate value. 3) Increase welding speed. |

| 6 | Headroom too small | 1) Too low welding current. 2) The arc voltage is too high. 3) Too high speed welding. | 1) Increase welding current. 2) Reduce the arc voltage. 3) Reduce welding speed. |

| 7 | Headroom is narrow and protruding | 1) The flux application width is small. 2) Arc voltage too low. 3) Too high welding speed. | 1) Increase the flux application width. 2) Increase the voltage of the electric arc. 3) Reduce welding speed. |

| 8 | nostril | 1) Rust or oiling at the joint. 3) Flux is contaminated. | 1) Clean and heat the joint. 2) Dry the flux for 1 hour at 150~300℃. 3) Clean the flux with a steel wire brush. |

| 9 | The surface of the welding line is rough-melted | 1) Excessive flux height. 2) The size of the flux granules is incorrectly selected. | 1) Reduce flux supply. 2) Select a flux that matches the welding current. |

| 10 | influxes | 1) Rust, oil or dirt on the bevel surface. 2) Damp flux (agglomeration type). 3) Too thick layer flux. | 1) Clean the bevel surface. 2) Dry for 1 hour at 150~300℃. 3) Reduce flux application thickness. |

VII. The balance of the linear speed of the movement of the product and the operating frequency of the converter

Note: The following parameters are for example only.

| Product linear speed (mm/min) | Operating frequency of main motor converter (Hz) | Assembly motor operating frequency (Hz) | ||

| 200 | 9.11 | 8.16 | ||

| 210 | 9.56 | 8.57 | ||

| 220 | 10.02 | 8.98 | ||

| 230 | 10.47 | 9.39 | ||

| 240 | 10.93 | 9.80 | ||

| 250 | 11.38 | 10.20 | ||

| 260 | 11.84 | 10.61 | ||

| 270 | 12.30 | 11.02 | ||

| 280 | 12.75 | 11.43 | ||

| 290 | 13.21 | 11.84 | ||

| 300 | 13.66 | 12.24 | ||

| 310 | 14.12 | 12.65 | ||

| 320 | 14.57 | 13.06 | ||

| 330 | 15.03 | 13.47 | ||

| 340 | 15.48 | 13.88 | ||

| 350 | 15.94 | 14.29 | ||

| 360 | 16.39 | 14.69 | ||

| 370 | 16.85 | 15.10 | ||

| 380 | 17.30 | 15.51 | ||

| 390 | 17.76 | 15.92 | ||

| 400 | 18.21 | 16.33 | ||

| 410 | 18.67 | 16.73 |

||

| 420 | 19.13 | 17.14 |

||

| 430 | 19.58 | 17.55 |

||

| 440 | 20.04 | 17.96 |

||

| 450 | 20.49 | 18.37 |

||

| 460 | 20.95 | 18.78 |

||

| 470 | 21.40 | 19.18 |

||

| 480 | 21.86 | 19.59 |

||

| 490 | 22.31 | 20 |

||

| 500 | 22.77 | 20.41 |

||

| 510 | 23.22 | 20.82 |

||

| 520 | 23.68 | 21.22 |

||

| 530 | 24.13 | 21.63 |

||

| 540 | 24.59 | 22.04 |

||

| 550 | 25.05 | 22.45 |

||

| 560 | 25.50 | 22.86 |

||

| 570 | 25.96 | 23.27 |

||

| 580 | 26.41 | 23.67 |

||

| 590 | 26.87 | 24.08 |

||

| 600 | 27.32 | 24.49 |

||

| 610 | 27.78 | 24.90 |

||

| 620 | 28.23 | 25.31 |

||

| 630 | 28.69 | 25.71 |

||

| 640 | 29.14 | 26.12 |

||

| 650 | 29.60 | 26.53 |

||

| 660 | 30.05 | 26.94 |

||

| 670 | 30.51 | 27.35 |

||

| 680 | 30.97 | 27.76 |

||

| 690 | 31.42 | 28.16 |

||

| 700 | 31.88 | 28.57 |

||

| 700 | 31.88 | 28.57 |

||

| 710 | 32.33 | 28.98 |

||

| 720 | 32.79 | 29.39 |

||

| 730 | 33.24 | 29.80 |

||

| 740 | 33.70 | 30.20 |

||

| 750 | 34.15 | 30.61 |

||

| 760 | 34.61 | 31.02 |

||

| 770 | 35.06 | 31.43 |

||

| 780 | 35.52 | 31.84 |

||

| 790 | 35.97 | 32.24 |

||

| 800 | 36.43 | 32.65 |

||

| 810 | 36.89 | 33.06 |

||

POWER DISTRIBUTION LINE

Manual

NM.01.000.000RE rev.01

Food distribution line

Thank you for purchasing our line.

We are confident that you have not wasted your money.

The power distribution line is intended for short-term storage

and distribution of first and second courses, hot and cold snacks and drinks, confectionery providing customers with cutlery

in system Catering.

The versatility of the distribution line and the complete set of modules on an individual order allows you to organize meals for various categories and groups of people of almost unlimited number at such facilities as: industrial enterprises, educational establishments, military units, canteens, cafes, etc.

The Atesi enterprise currently produces 3 types of food distribution lines - Bella-Neva and Bella-Nota and the Bella-Nota mobile food distribution line - a mobile distribution line with folding tray guides, the modules of which are equipped with wheels.

Full set power distribution line includes the following modules:

Rack for cutlery and bread Refrigerated showcase Bain-marie for first courses (for "Bella-Nota" 1 and 2 burners, for "Bella-Neva" 2 and 3 burners) Bain-marie for second courses (dry and wet heating ) Neutral table Cold table Cash desk (3 modifications: frontal, with right and left armrest) 8 Rotary module (with external or internal rotation by 90°) Module for warming plates Bella-Nota line is a mini line version, it is very convenient for use in places with limited space, but with a capacity that is almost equal to a line of a higher class

- "Bella-Neva". The low price of the Bella-Nota line is ensured by the smaller dimensions of some modules in comparison with BellaNeva.

НМ.01.000.000РЭ rev.01 Bella-Nota mobile distribution line modules allow organizing power distribution in any place where it is possible to connect to a 220 V electrical network.

The modules are equipped with four wheels, two of which are equipped with a brake to fix the module.

The modules of the Bella-Neva food distribution line have larger overall dimensions than the modules of Bella-Note, and are almost completely made of food grade stainless steel, which greatly simplifies the sanitary and hygienic processing of this line and increases its service life. In addition, all shelves of the Bella-Neva line are equipped with lighting, which provides it with a wider range of applications (shaded or dimly lit rooms). On the part of consumers, the modules of the Neva and Nota lines are equipped with protective glasses that protect dishes from dust. In the Neva line, glass restricts consumer access to dishes.

The design of the line modules is thought out in such a way that it is easy to carry out a thorough sanitization of all surfaces in contact with food products during operation.

Distribution lines can be installed in a straight line or, using swivel modules, in corner combinations with both external and internal rotation.

Each distribution line module is self-contained, so it is not necessary to purchase a complete line kit. You can choose the modules you need at your own discretion.

When purchasing our food distribution line, carefully read the rules for its operation. This will allow you to successfully use it and do your business.

Atesi is constantly expanding and improving the range of its products, so the actual set and technical characteristics of the modules may differ slightly from those indicated in this passport without deteriorating consumer properties.

NM.01.000.000RE amend.01 Operation manual for the power distribution line.

1. General instructions.

1.1. The power distribution line operates on 50 Hz, 220 V ±10% AC power with an additional ground wire.

1.2. Climatic conditions for line operation: ambient air temperature from 10°С to +35°С; relative humidity no more than 60% at a temperature of +20°С.

When operating the line modules in a territory with a maritime climate, the modules must be installed in indoors with air conditioning.

1.3. Connecting the electrical power to the stationary modules of the distribution line is carried out by pipe wiring hidden in the floor. The wire diameter must be calculated based on the total load current of the connected modules. Pipe diameter not less than (12 mm). The height of the pipe outlet from the floor is 90 ... 100 mm. Places for connecting pipe outlets of electrical power to the modules are located in the left near corner from the side of the service personnel.

1.4. When installing modules equipped with shelves with lighting, it is necessary to connect the electrical power to the lamp. Why pass the conductor (brought to the module table top) through the left rack of the shelf and connect it to the terminal on the shelf according to the electrical diagram.

1.5. Mobile modules of the power distribution line are connected to the mains by means of an electrical cord and plug, which the modules are equipped with. The length of the electrical cord is at least 1.5 m.

1.6. Mobile modules are installed and connected to the mains by the consumer.

1.7. The movement of mobile modules should be carried out on even surfaces, avoiding impacts on thresholds, steps and other uneven surfaces.

1.8. All work related to connecting the line modules to the mains must be carried out by a qualified specialist with a permit to work with electrical equipment.

1.9. The electrical network to which the distribution line is connected must be equipped with a separate shield with an automatic switch of the AK-50 type for a load current not less than the total load current of all connected modules according to the table.

1.10. The line is installed on a flat, horizontal, hard floor (tile, marble, ceramics, etc.) НМ.01.000.000РЭ rev.01

1.11. Assembly of modules (installation of guide trays, shelves, etc.) before installation of the line must be carried out in strict accordance with the assembly instructions attached to the packaging of each module.

1.12. Protect the line from careless handling and blows. Regularly sanitize the working surfaces of the line at the end of the working day.

– – –

the actual power consumption and load current are determined by additionally connected devices, the total power of which must not exceed that indicated in the table.

power consumption and load current are determined by the type of cash register.

2.1. Neutral modules of the power distribution line 2.1.1. Neutral table module

Designed for dispensing various drinks, confectionery, etc., as well as for installing an additional auxiliary equipment or appliances (coffee machines, system equipment fast food etc.), for which the module is provided with a power supply and a euro socket is placed on the front panel.

Attention! It is forbidden to connect equipment and devices with a total power consumption of more than 2.2 kW to the electrical socket of the Neutral Table module.

The neutral table of the Neva distribution line is additionally equipped with an intermediate shelf, which allows more rational use of its internal volume.

NM.01.000.000RE rev.01 Bella-Nota Bella-Neva Mobile Bella-Nota 2.1.2. Module for cutlery and bread.

Designed for short-term storage and distribution of cutlery, trays and bakery products.

The module is made in the form of three functional blocks:

Cabinet with a niche for storing and issuing trays;

Cutlery block (4-section) in the distribution line "Neva"

it is completed with seamless stainless gastroyemkost as much as possible convenient for sanitary processing. In the distribution line "Nota" - 3 welded stainless containers have a perforated bottom, as a result of which drops of moisture flowing down from the tools do not stagnate in it, ensuring the best sanitary and hygienic condition of cutlery;

Bella-Neva Bella-Nota Bella-Nota mobile NM.01.000.000RE rev.01

Block for bakery products. In the distribution line "Neva" there is a 2-section cabinet, divided into sections by an inclined shelf, which allows not only laying out bakery products for direct distribution, but also storing them for prompt replenishment. In the "Note" distribution line, the block is a stand with stops for a standard table tray.

2.1.3. Checkout module.

It is intended for the equipment of a workplace of the seller - the cashier.

It is equipped with a euro socket for connecting a cash register and a metal lockable box for storing banknotes. In the Bella-Neva line, there are three modifications of the Cash Desks: front without an armrest, side with an armrest on the right, and side with an armrest on the left. Each of the modifications allows you to orient workplace cashier relative to the buyer face, right or left side, respectively. The cash desk with an armrest can be rebuilt into another modification - with a different arrangement of the cash desk table (right or left). The cash table with an armrest is equipped with a stand for folding small items.

Cash desk with Cash desk Cash desk with armrest universal Universal Bella-Neva Bella-Nota Bella-Neva 2.1.4. Rotary module.

It is designed to provide the possibility of turning the distribution line at an angle of 90° to the inner (Inner rotary module) or outer (external rotary module) sides.

НМ.01.000.000РЭ rev.01 On the service personnel side, the swivel module has an open niche that can be used to store inventory, etc. the possibility of overturning the module, for example, by pressing its tray guides.

– – –

2.2. Thermal equipment 2.2.1. Module "Bain-marie first courses"

Designed to keep hot containers (boilers) with first courses. It has 6 levels of temperature adjustment, allowing you to maintain the temperature of the first dishes from the temperature environment to a boil. Position "0" of the temperature controller (heating off) corresponds to the vertical position of the handle (zero at the top point). Turning the regulator knob clockwise, the heating power changes from maximum (position 6) to minimum (position 1). In the Neva distribution line, the leftmost switch turns on the backlight lamp on the shelf and on the front panel of the module.

Attention! It is forbidden to use containers with a bottom diameter smaller than the diameter of the electric hotplate for heating dishes. This can lead to premature failure.

Attention! It is forbidden to operate the food warmer with the included burners without load (without containers)!

Bella-Neva Bella-Nota

2.2.2. Module "Bain-marie second courses".

Designed to keep gastroyemkost with garnishes and seasonings of second courses in a hot state.

At the request of the customer, it is completed with standard seamless gastronorm containers of three sizes:

530 x 325 x 100; 530 x 325 x 150; 265 x 325 x 150.

The Atesi enterprise produces food warmers for second courses of “dry” and “wet” heating.

Heating of products in a "dry" food warmer is carried out with the help of heating elements located under each gastronorm container. Sectional partitions installed in the bain-marie bath provide the necessary temperature in each separate section"dry" food warmer.

Bella-Neva Bella-Nota Bella-Nota 10 mobile NM.01.000.000RE rev.01 Heating of each heating element of a “dry” food warmer is switched on by a separate button located under the corresponding section of the food warmer. The far left switch turns on the illumination of the shelf ("Neva").

Heating of containers in food warmers of "wet" heating is carried out with the help of hot steam, the temperature of the water inside the bath does not exceed 100°C and the products do not burn. The temperature regulator smoothly regulates the temperature of the water in the bath. A faucet with a hose is provided to drain the water from the bath.

Attention! The volume of water in the bathtub of "wet" heating bain-marie should be up to a level not lower than "MIN" and not higher than the level "MAX".

Check the water level periodically and top up if necessary.

2.2.3. Plate warmer module.

The module is designed to heat plates of various diameters from 150 mm to 360 mm. Special limiters allow you to fix the stacks of plates of different diameters.

The presence of heated plates on the food distribution line ensures that the food served on them cools much more slowly than on plates without heating.

The plates are stacked on the basis of a lifting spring mechanism built into the elevator body. At full load, a small (up to 8-10 pieces) number of plates remains above the surface of the elevator, and the remaining plates (about 30-35 pieces) are in a heated volume.

The design provides heating of plates within 30 ° - 60 °C.

As the plates are removed, the mechanism automatically lifts the next batch (2-3 pieces) to the surface of the elevator.

The plates are heated by a heating element with a power of 0.27 kW, which is located at the bottom of the module under the elevator for feeding the plates.

– – –

Bella-Neva Bella-Nota Mobile Bella-Nota The module consists of three functional blocks:

Table-cabinet;

Refrigeration showcase; - upper box

The table-cabinet is divided into two independent compartments - aggregate and main. The aggregate compartment houses the compressor, condenser and mounting elements refrigeration unit. It is separated from the main one by a partition and closed with a door with a lock (Bella-Neva) or a removable panel (Bella-Nota). For reliable operation of the compressor, it is necessary to clean the radiator of the condenser block at least once a month (for example, with a vacuum cleaner), for which there is a removable panel on the front side of the aggregate compartment. To remove the front or rear panel, you must first unscrew the two bolts at the bottom of the panel and remove it from the upper hook. The main compartment has two doors and can be used to store inventory. The volume of this compartment is not cooled.

The refrigerated display case is equipped on the staff side with two sliding doors, and on the customer side:

In the line "Bella-Neva"

HM.01.000.000RE rev.01 has three rows, and in the Bella-Nota line there are two rows of folding doors.

For displaying products there are: in the Bella-Neva line - two, and in the Bella-Nota line - one level of lattice shelves. The working chamber of the showcase is illuminated by a built-in lamp with a fluorescent lamp.

The refrigeration system uses refrigerant R22 freon.

The upper box is designed to accommodate the air cooler and mounting elements of the refrigeration unit. This arrangement of the air cooler allows you to quickly cool the entire volume of the showcase.

To control the operation of the showcase on the front panel are located:

illuminated pushbutton switch "0" - "1" to turn on the compressor, illuminated pushbutton switch "light" to turn on the showcase lighting, digital display to display information about the showcase operation mode.

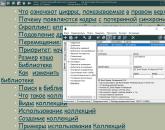

The digital display allows you to program any operating mode of the refrigerated showcase. The most optimal mode has been set at the Atesi enterprise and, for the purpose of involuntary reprogramming, a code has been introduced that excludes access to changing the operating mode of the refrigerated display case.

If it is necessary to reprogram the operating mode, please contact the manufacturer. The refrigerated display cases are set to the following operating mode: compressor operation until the temperature reaches +2°С (at full load no more than 1 hour), compressor shutdown, when the temperature rises to +8°С, the compressor is switched on again, etc. To improve the operation of the air cooler, every 2 hours the forced defrost mode is activated, the compressor stops and the air cooler is defrosted for 15 minutes, then the entire cycle of the showcase operation is repeated.

The module operates in the mode of frequent door opening. Warm air from the environment constantly penetrates into the refrigerated volume, therefore, temperature unevenness across the volume of the refrigerated chamber is possible. The temperature in the room where the module is installed should not exceed 25°C, otherwise the refrigeration unit will work with overload and it will take more time to reach set mode cooling.

To collect condensate from the evaporator, the showcase is equipped with a drain tray, which is located: in the Bella-Nota lines directly under the air cooler in the volume of the working chamber; in BellaNeva lines on the lower frame of the module under the aggregate compartment. Periodically monitor the level of condensate in the trays. The accumulated moisture must be drained at the end of each working day, and at high humidity, temperature and frequent opening of the showcase doors, at least after 4 hours.

For reliable and durable operation of the showcase, it is not recommended to place it close to heating equipment, heating radiators, etc., as well as in direct sunlight. Do not block the blinds of the aggregate compartment.

To illuminate the internal volume of the refrigerated showcase, it is necessary to install a lighting lamp in the mounting sockets. Then put a protective glass into the channel fixer and fix it with self-tapping screws at the top of the glass part near the lamp.

2.3.2. Cold table module

It is intended for storage, demonstration and sale of drinks and food. Cooling takes place in the volume of a special niche of the countertop with the help of an evaporator fixed to the bottom of the bath.

Functionally, the "Cold Table" corresponds to the cabinet-table of the "Refrigerating Showcase" module. Approximate temperature in the cooled volume ranges from -2°C on the surface to +10°C at a height of 60 mm from the bath surface. Depending on the operating conditions of the module (temperature, relative humidity, etc.), it is possible to adjust its operation mode using the temperature controller located in the upper part of the aggregate compartment. The temperature is lowered by turning the knob clockwise. Cooling occurs due to the refrigerant - freon R22. Overall dimensions of the module bath allow using a set of standard gastronorm containers. To drain the condensate from the bath, it has a drain fitting.

Bella-Nota Bella-Neva Bella-Nota mobile

NM.01.000.000RE rev.01

3. Safety requirements and fire safety.

3.1. The modules of the power distribution line are made with protection against defeat electric shock according to class I according to GOST R IEC 335-1-94, degree of protection according to GOST 14254 - IP20.

3.2. Line modules must be additionally grounded with a busbar with a cross section of at least 2.5 mm (the grounding bolt is located on the left side of the bottom frame of the module).

3.3. The line must be connected to the electrical network from a separate circuit breaker.

The connection diagram of the modules is given in reference appendix 5.

3.4. The Movable Dispense Line Modules must only be used with a socket that has a protective earth connection.

3.5. Attention! The temperature of the electric hotplates of the food warmer of the first courses and the heating elements of the food warmer of the second courses is high. Do not allow open areas of the body to touch the heating elements.

3.6. After finishing work on the distribution line, set the electrical switches of the modules to the “0” position. Disconnect the distribution line from the mains using the main mains switch.

3.7. It is forbidden to work on the line with open doors, removed covers, damaged glasses, faulty electrical components.

4. Preparation for work and order of work.

4.1. Check the straightness of the installation of the distribution line modules. Tray rails should fit snugly against each other without steps. If necessary, using the adjustment of the legs, align the modules according to the level. After unpacking, keep the modules at room temperature for at least 2 hours.

Under the refrigeration unit (Bella-Neva), install a condensate collection tray along the guides. As it fills, it is necessary to pour out the accumulated liquid.

4.2. The distribution line modules are controlled from the control panel of the respective modules.

4.3. Before starting work, check the hygienic condition of the distribution line. All surfaces must be clean, shelves and containers must be washed and dried. Glass must not be cracked.

4.4. Turn on the refrigerated showcase, food warmer of the first and second courses with the corresponding electrical switches.

НМ.01.000.000РЭ rev.01 Time to enter the mode is not more than 1 hour for a refrigerated display case, a cold table, a “wet” food warmer, no more than 20 minutes for a food warmer for first courses and a “dry” food warmer for second courses. To speed up the exit of the “wet” food warmer to the operating mode, it is recommended to pour hot boiled water into the bath.

4.5. Before turning on the heating elements of food warmers of the second courses, it is necessary to put sectional partitions and, if necessary, put non-stick screens on the heating elements.

4.6. After entering the mode of refrigeration modules, as well as food warmers of the first and second courses, make a bookmark of products. Put cutlery in the tool module, lay buns or sliced bread, put clean trays on the lower block of the module. The line is ready to go.

4.7. In preparation for the operation of a mobile distribution line, it is necessary to install the modules on a flat horizontal surface.

4.7.1. Fix each module with a brake on the wheels.

4.7.2. Swing-out tray rails are aligned with fixing bolts – by releasing the bolts, the tray rails are aligned in height and fixed.

4.8. Shutdown order.

After finishing work, set the switches for food warmers of the first and second courses, refrigeration modules to position "0".

Empty the line modules from the products. Remove the boilers (or containers) from the food warmers of the first courses, the gastronorm containers from the food warmers of the second courses.

Attention! In order for the food warmer electric burners of the first courses to serve for a long time, do not leave them switched on without containers installed on them, in order to avoid overheating.

Attention! For more effective work refrigerated showcase, food and drinks, before laying in it must be cooled to ambient temperature.

Attention! For more efficient operation, refrigeration modules are not recommended to be installed in close proximity to food warmers of the first and second courses and other heating equipment.

5. Maintenance of the food distribution line.

5.1. All maintenance work is carried out with the line disconnected from the network.

5.2. Maintenance work must only be carried out by qualified personnel.

5.3. Every day at the end of work, it is necessary to thoroughly clean the food distribution line from food residues, condensate, grease, etc.

NM.01.000.000RE rev.01 Use for this standard means cleaning. After cleaning the line, wipe all surfaces with dry cloths. Dry the gastronorm containers that are part of the distribution line.

5.4. As the condenser gets dirty, which can lead to failure of the compressor of the refrigeration unit, but at least once a month, it is necessary to clean it compressed air or vacuum cleaner.

5.5. Pay attention not only to the cleanliness of the food distribution line, but also to the condition of the floor around it, as the presence of liquid or fat on the floor is a path to injury.

6. Warranty.

Size: px

Start impression from page:

transcript

1 SELF-SERVICE POWER LINE Operation manual ATESY

2 Self-service food distribution line Thank you for purchasing our line. We are confident that you have not wasted your money. Technical description. The food distribution line is designed for short-term (up to 4-6 hours) storage and distribution of first and second courses, hot and cold snacks and drinks, confectionery products, providing customers with cutlery and utensils in the catering system. The versatility of the distribution line and the completion of individual modules allows you to organize meals for various categories and groups of people of almost unlimited number at such facilities as: industrial enterprises, educational institutions, military units, canteens, cafes, etc. The Atesi enterprise currently produces 3 types of food distribution lines "Bella-Neva" and "Bella-Nota" and the food distribution line "Bella-Nota mobile" - a mobile distribution line with folding tray guides, the modules of which are equipped with wheels. A complete set of food distribution line includes the following modules: 1 Rack for cutlery and bread 2 Refrigerated showcase 3 Food warmer for first courses (for "Bella-Nota" 1 and 2 burners, for "Bella-Neva" 2 and 3 burners) 4 Second course food warmer (dry and wet heating) 5 Neutral table 6 Cold table 7 Cash table (3 modifications: frontal, with right and left armrest) 8 Rotary module (with external or internal rotation by 90) 9 Plate warmer module (for Bella Nota line) 2

3 Line "Bella-Nota" is a variant of a mini-line, it is very convenient for use in places with a limited area, however, with a capacity that is practically not inferior to the line of a higher class - "Bella-Neva". The low price of the Bella-Nota line is ensured by the smaller dimensions of some modules in comparison with the Bella-Neva, as well as the manufacture of body elements that cannot come into direct contact with food during operation, made of galvanized steel. Mobile distribution modules allow you to organize power distribution lines in any place where there is an electrical supply. The modules are equipped with four wheels, two of which are equipped with a brake to fix the module. Mobile line modules have an open shelf, the front panel of the module can be backlit. The modules of the Bella Neva food distribution line have the maximum overall dimensions of those produced by the Atesi enterprise, and are almost completely made of food grade stainless steel, which greatly simplifies the sanitary and hygienic processing of this line and increases its service life. In addition, all shelves of the Bella Neva line are equipped with lighting, which provides it with a wider range of applications (shaded or dimly lit rooms). On the part of consumers, the modules of the Neva and Nota lines are equipped with sanitary protective glasses that prevent food from getting dusty. In the Neva line, glass restricts consumer access to dishes. The design of the line modules is thought out in such a way that it is easy to carry out a thorough sanitization of all surfaces in contact with food during operation. Distribution lines can be installed in a straight line or, using swivel modules, in corner combinations with both external and internal rotation. Each distribution line module is self-contained, so it is not necessary to purchase a complete line kit. you can 3

4 choose the modules you need at your own discretion. When purchasing our food distribution line, carefully read the rules for its operation. This will allow you to successfully use it and do your business. Atesi is constantly expanding and improving the range of its products, so the actual set and technical characteristics of the modules may differ slightly from those indicated in this passport without deteriorating consumer properties. 1. General instructions. Power Distribution Line Operation Manual The power distribution line operates on AC mains with a frequency of 50 Hz and a voltage of 220 V ±10% with an additional grounding wire. Climatic conditions for the line operation: ambient air temperature from 0 С to +25 С; relative humidity is not more than 60% at a temperature of +20 C. Connection of electrical power to the stationary modules of the distribution line is carried out by pipe wiring hidden in the floor. The wire diameter must be calculated based on the total load current of the connected modules. Pipe diameter not less than ½ (21 mm). Height of the pipe outlet from the floor mm. See the drawings of the modules for the places where the pipe outlets of the electrical power supply are connected to the modules. When installing modules equipped with shelves with lighting, it is necessary to connect the electrical power to the lamp. Why pass the conductor (brought to the module table top) through the left rack of the shelf and connect it to the terminal on the shelf according to the electrical diagram.

5 modules are provided. An electrical cord with a length of at least 1.5 m is wound on special brackets located under the module housing Mobile modules are installed and connected to the power supply by the consumer Moving the mobile modules should be carried out on even surfaces, avoiding hitting thresholds, steps and other uneven surfaces All related work with the connection of the line modules to the power grid must be carried out by a qualified specialist with permission to work with electrical equipment. The electrical network to which the distribution line is connected must be equipped with a separate shield with an automatic switch of the AK-50 type for a load current not less than the total load current of all connected modules according to table The line is installed on a flat, horizontal, hard floor (tile, marble, ceramics, etc.) Before installing the line, assembly of modules (installation of guide trays, shelves, etc.) must be carried out in strict accordance with the assembly instructions attached to the package of each module Protect the line from rough handling and shock. Regularly sanitize the working surfaces of the line at the end of the working day. 2. Specifications power distribution line modules. Name of the module, designation 1 Module for table. appliances and bread: Neva (with a cabinet for bread) Nota Nota-mobile. Overall dimensions, mm (length x width x height) 700 х 700 х 700 х 700 х 1314 power kW Operating temperature, C Loading current, max., A

6 2 Refrigerated showcase: Neva Nota Nota-movable. 3 Food warmer 1 course: Neva 2 burners. Neva 3 confor. Note 2-confor. Note 1-o confor. 4 Bain-marie 2 dishes: Neva (dry heating) Neva (moist heating) Nota (dry heating) Nota (wet heating) Nota-movable. 5 Neutral table Neva Nota Note-moving. 6 Cold table: Neva Nota Note-mobile. 7 Cash desk: Neva with armrest Neva station wagon. Universal note. mobile Note universal. 8 Rotary module: Neva (internal) Neva (external) Nota (internal) Nota (external) х х1000х х1015х х 1019х х1000х х1015х х1019х х 1000х х 1000 х х 1015 х х 1015 х x 866 x x 777 x x 853 x x 788 x 870 0.75 0.65 0.65 5.25 7.85 5.25 2.65 1.24 1.24 0.9 0.9 0.9 2 ,2 2.2 2.2 0.5 0.45 0.45 2.2 2.2 2.2 2.2 Inside the chamber On the surface of the burner 300 Inside the volume of gastronorm containers 80 At H=10 mm Module for heating plates 700 х1017х1045 0.5 4.5 4.5 2,

7, the actual power consumption and load current are determined by additionally connected devices, the total power of which should not exceed that indicated in the table. power consumption and load current are determined by the type of cash register used Neutral modules of the power distribution line Neutral table module Designed for dispensing various drinks, confectionery, etc., as well as for installing additional auxiliary equipment or fast food, etc.), for which the module is provided with a power supply and a Euro socket on the front panel. Attention! It is forbidden to connect equipment and devices with a total power consumption of more than 2.2 kW to the electrical socket of the Neutral Table module. The neutral table of the Neva distribution line is additionally equipped with an intermediate shelf, which allows more rational use of its internal volume. Bella-Neva Bella-Nota Bella-Nota mobile 7

8 Cutlery and bread module. Designed for short-term storage and distribution of cutlery, trays and bakery products. The module is made in the form of three functional blocks: - cabinet with a niche for storing and issuing trays; - a cutlery block (4-section) in the Neva distribution line is completed with seamless stainless gastronorm containers that are as convenient as possible for sanitization. In the distribution line "Nota" 3, welded stainless containers have a perforated bottom, as a result of which drops of moisture flowing down from the tools do not stagnate in it, providing a better sanitary and hygienic condition of cutlery; - block for bakery products. In the distribution line "Neva" there is a 2-section cabinet, divided into sections by an inclined shelf, which allows not only laying out bakery products for direct distribution, but also storing them for prompt replenishment. In the "Note" distribution line, the block is a stand with stops for a standard table tray. Bella-Neva Bella-Nota Bella-Nota mobile 8

9 Cash desk module. It is intended for the equipment of a workplace of the seller of the cashier. It is equipped with a euro socket for connecting a cash register and a metal lockable box for storing banknotes. In the Bella-Neva line, there are three modifications of the Cash Desks: front without an armrest, side with an armrest on the right, and side with an armrest on the left. Each of the modifications allows you to orient the cashier's workplace relative to the buyer with his face, right or left side, respectively. The cash table with armrest can be rebuilt into another modification with a different arrangement of the cash table (right or left). The cash table with an armrest is equipped with a stand for folding small items. Universal cash desk Bella-Neva Universal cash desk Bella-Nota Cash desk with armrest Bella-Neva 9

10 Rotary module. It is designed to provide the possibility of turning the distribution line at an angle of 90 to the inner (Inner rotary module) or outer (external rotary module) sides. On the part of the service personnel, the rotary module has an open niche that can be used for storing inventory, etc. When installing the module in a line, it is necessary to screw the support legs (included in the delivery package) to the lower frame of the module, which prevent the possibility of the module tipping over, for example, when you press it tray guides. Bella-Neva (internal) Bella-Neva (external) Bella-Nota (internal) Bella-Nota (external) 10

11 2.2. Thermal equipment Module "Bain-marie first courses" Designed to keep containers (boilers) with first courses in a hot state. It has 6 levels of temperature adjustment, allowing you to maintain the temperature of the first dishes from ambient temperature to boiling. Position "0" of the temperature controller (heating off) corresponds to the vertical position of the handle (zero at the top point). Turning the regulator knob clockwise, the heating power changes from maximum (position 6) to minimum (position 1). The illuminated pushbutton switch, located to the left of the regulator knob, turns the regulator on or off. In the Neva distribution line, the leftmost switch turns on the backlight on the shelf and on the front panel of the module. Attention! It is forbidden to use containers with a bottom diameter smaller than the diameter of the electric hotplate for heating dishes. This can lead to premature failure. Attention! It is forbidden to operate the food warmer with the included burners without load (without containers)! Bella-Neva Bella-Nota 11

12 Module "Bain-marie second courses". Designed to keep gastroyemkost with garnishes and seasonings of second courses in a hot state. At the request of the customer, it is completed with standard seamless gastronorm containers of three sizes: 530 x 325 x 100; 530 x 325 x 150; 265 x 325 x 150 (100). Heating of products is carried out by means of heating elements located under each gastroyemkost. Sectional partitions installed in the bain-marie bath allow to provide the necessary temperature in each separate section of the bain-marie. The Atesi enterprise produces food warmers for second courses of “dry” and “wet” heating. Since the heating of containers in wet heating food warmers is carried out using hot steam, the temperature inside the bath does not exceed 100 ° C and the products do not burn. Bella-Nota Bella-Nota mobile Bella-Neva 12

13 Heating of each heating element of the food warmer is switched on by a separate button located under the corresponding section of the food warmer. The far left switch turns on the illumination of the shelf ("Neva"). Attention! The volume of water in the baths of the "wet" heating bain-marie is designed for 4 hours of continuous operation until it is completely boiled away. Periodically check the water level and top up if necessary. The module is designed to heat plates of various diameters from 150 mm to 360 mm. Special limiters allow you to fix the stacks of plates of different diameters. The presence of heated plates on the food distribution line ensures that the food served on them cools much more slowly than on plates without heating. The plates are stacked on the basis of a lifting spring mechanism built into the elevator body. At full load, a small (up to 8-10 pieces) number of plates remains above the surface of the elevator, and the remaining plates (about a piece) are in a heated volume. The design provides heating of the plates within C. As the plates are removed, the mechanism automatically lifts the next batch (2-3 pieces) to the surface of the elevator. The plates are heated by a heating element with a power of 0.27 kW, which is located at the bottom of the module under the elevator for feeding the plates. Bella Nota 13

14 2.3. Refrigerating Equipment “Refrigerating Showcase” Module Designed for short-term (up to 4 hours) storage and distribution of chilled drinks, salads, fermented milk products and other dishes that require chilled storage. Note. When stored for more than 4 hours, salads and other snacks may become “weathered” and lose their presentation. Bella-Nota Bella-Nota mobile Bella-Neva 14

15 The module consists of three functional blocks: - table-cabinet; -refrigeration showcase; - upper box The table-cabinet is divided into two independent compartments - aggregate and main. The aggregate compartment houses the compressor, condenser and refrigeration installation elements. It is separated from the main one by a partition and closed with a door with a lock (Bella-Neva) or a removable panel (Bella-Nota). For reliable operation of the compressor, it is necessary to clean the radiator of the condenser block at least once a month (for example, with a vacuum cleaner), for which there is a removable panel on the front side of the aggregate compartment. To remove the front or rear panel, you must first unscrew the two bolts at the bottom of the panel and remove it from the upper hook. The main compartment has two doors and can be used to store inventory. The volume of this compartment is not cooled. The refrigerating display case is equipped on the staff side with two sliding doors, and on the customer side: - in the Bella-Neva line there are three rows, and in the Bella-Nota line there are two rows of folding doors. For displaying products there are: in the Bella-Neva line - two, and in the Bella-Nota line - one level of lattice shelves. The working chamber of the showcase is illuminated by a built-in lamp with a fluorescent lamp. Freon-22 refrigerant is used in the refrigeration system. The upper box is designed to accommodate the air cooler and mounting elements of the refrigeration unit. This arrangement of the air cooler allows you to quickly cool the entire volume of the showcase. To control the operation of the showcase on the front panel, there are: a push-button switch with backlight "power" to turn on the compressor, a push-button switch with backlight "light" to turn on the showcase lighting, a digital display to display information about the showcase's operation mode. The digital display allows you to program any operating mode of the refrigerated showcase. At the enterprise "Atesi" the most optimal mode is set and in order to

16 free reprogramming, a code was introduced that excludes access to changing the operating mode of the refrigerated display case. If it is necessary to reprogram the operating mode, please contact the manufacturer. The refrigerated display cases are set to the following operating mode: compressor operation until the temperature reaches +2 C (at full load no more than 1 hour), compressor shutdown, when the temperature rises to +8 C, the compressor is restarted, etc. To improve the operation of the air cooler, every 2 hours the forced defrost mode is activated, the compressor stops and the air cooler is defrosted for 15 minutes, then the entire cycle of the showcase operation is repeated. The module operates in the mode of frequent door opening. Warm air from the environment constantly penetrates into the cooled volume, so the temperature unevenness over the volume of the cooled chamber is 5 C. The temperature in the room where the module is installed should not exceed 25 C, otherwise the refrigeration unit will work with overload and it will take more time to exit to the set cooling mode. To collect condensate from the evaporator, the showcase is equipped with a drain tray, which is located: in the Bella-Nota lines directly under the air cooler in the volume of the working chamber; in the Bella-Neva lines on the lower frame of the module under the aggregate compartment. Periodically monitor the level of condensate in the trays. The accumulated moisture must be drained at the end of each working day, and in case of high humidity, temperature and frequent opening of the showcase doors, at least after 4 hours. For reliable and durable operation of the showcase, it is not recommended to place it close to heating equipment, heating radiators, etc. ., as well as in places exposed to direct sunlight. Do not block the blinds of the aggregate compartment. To illuminate the internal volume of the refrigerated showcase, it is necessary to install a lighting lamp in the mounting sockets. Then, put a protective glass into the channel-locker and fix it with self-tapping screws at the top of the glass part near the lamp. 16

17 Cold table module Designed for storage, demonstration and sale of drinks and food. Cooling takes place in the volume of a special niche of the countertop with the help of an evaporator fixed to the bottom of the bath. Functionally, the "Cold Table" corresponds to the cabinet-table of the "Refrigerating Showcase" module. The temperature in the cooled volume is provided within the range from -2 C on the surface to +10 C at a height of 60 mm from the bath surface. Depending on the operating conditions of the module (temperature, relative humidity, etc.), it is possible to adjust its operation mode using the temperature controller located in the upper part of the aggregate compartment. The temperature is lowered by turning the knob clockwise. Cooling occurs due to the refrigerant freon-22. Overall dimensions of the module bath allow using a set of standard gastronorm containers. To drain the condensate from the bath, it has a drain nipple. The procedure for removing condensate is the same as in the "Refrigerated Showcase". Bella-Nota Bella-Nota mobile Bella-Neva 17

18 3. Safety and fire safety requirements Power distribution line modules are designed with protection against electric shock according to class 1 according to GOST, degree of protection according to GOST R Line modules must be additionally grounded with an open wiring bus with a cross section of at least 2.5 mm (ground bolt located on the left side of the bottom frame of the module) The line must be connected to the electrical network from a separate circuit breaker. The connection diagram of the modules is given in the reference appendix. The modules of the mobile distribution line must be used only with a socket having a protective earth. Attention! The temperature of the electric hotplates of the food warmer of the first courses and the heating elements of the food warmer of the second courses is high. Do not allow open areas of the body to touch the heating elements After finishing work on the distribution line, set the electrical switches of the modules to the “off” position. Disconnect the distribution line from the electrical network using the general mains switch. It is forbidden to work on the line with open doors, removed covers, damaged glasses, faulty electrical elements. 4. Preparation for work and order of work Control of the modules of the distribution line is carried out from the control panel of the corresponding modules Before starting work, check the hygienic condition of the distribution line. All surfaces must be clean, shelves and containers must be washed and dried. Glass should not have cracks and stains from water stains. 18

19 4.3. Turn on the refrigerated showcase, food warmer of the first and second courses with the corresponding electrical switches. The time to enter the mode is no more than 1 hour for a refrigerated display case and a cold table, no more than 20 minutes for food warmers of the first and second courses Check the straightness of the installation of the distribution line modules. Tray rails should fit snugly against each other without steps. If necessary, using the adjustment of the legs, align the modules according to the level. Install a drip tray under the refrigeration unit along the guides to collect condensate. As it fills, it is necessary to pour out the accumulated liquid 4.5. Before turning on the heating elements of the food warmers of the second courses, it is necessary to put sectional partitions and, if necessary, put on non-stick screens on the heating elements. Put cutlery in the tool module, lay buns or sliced bread, put clean trays on the lower block of the module. The line is ready for operation When preparing for the operation of the mobile distribution line, it is necessary to install the modules on a flat horizontal surface. Fix each module with a brake on the wheels. Unwind the electrical wire by removing it from the bracket. The bracket is located under the module tabletop. The tilting tray rails are aligned with the fixing bolts, releasing the bolts, the rails are aligned in height and fixed. Disconnection order. After finishing work, set the switches for food warmers of the first and second courses, refrigeration modules to the “Off” position. Empty the line modules from the products. Remove the boilers (or containers) from the food warmers of the first courses, the gastronorm containers from the food warmers of the second courses. 19

20 Attention! In order for the food warmer electric burners of the first courses to serve for a long time, do not leave them switched on without boilers (or containers) installed on them, in order to avoid overheating. Attention! For more efficient operation of the refrigerated display case, food and drinks must be cooled to ambient temperature before being put into it. Attention! For more efficient operation, refrigeration modules are not recommended to be installed in close proximity to food warmers of the first and second courses. 5. Maintenance of the power distribution line All maintenance work is carried out with the line disconnected from the mains Maintenance work is performed only by qualified specialists From unauthorized access to the microprocessor of the refrigerated display case, the company sets a lock code Every day at the end of the work, it is necessary to thoroughly clean the power distribution line from food residues, condensate, grease, etc. Use standard cleaning agents for this. After cleaning the line, wipe all surfaces with dry cloths. Dry the gastronorm containers that are part of the distribution line. Install gastronomy containers in place As the condenser gets dirty, which can lead to failure of the compressor of the refrigeration unit, but at least once a month, it is necessary to clean it with compressed air or a vacuum cleaner Pay attention not only to the cleanliness of the power distribution line, but also to the condition the floor around her, because the presence of liquid or fat on the floor is a path to injury. 20

21 6. Warranty obligations Atesi guarantees the normal operation of the power distribution line for 12 months from the date of sale, provided that the rules of use set forth in this manual are observed as a result of non-compliance with the requirements set forth in the instruction manual Exchange and return of a product of good quality is carried out within 15 days from the date of purchase of the product only if the following requirements are met: the presence of an instruction manual for this product; availability of a payment document; availability of factory packaging; the product must be clean appearance, without mechanical damage; no unauthorized repairs were made 6.4. Warranty period of storage 12 months from the date of issue During the warranty period, the company performs warranty repairs, and after the end of the warranty period, concludes contracts for qualified post-warranty service by phone: (495) By this phone you can find out a complete list of products manufactured by the company. 21

22 7. Appendix. (Principal electrical circuits modules) Appendix 1 Module "Bain-marie" of the power distribution line Schematic diagram X2 Ground bolt 1 X1 3-terminal network block 1 S1, S2 Switch with indication 2 E3, E4 Electric burner 2 kW 2 E1, E2 Temperature controller 6-speed 222

23 Appendix 2 Module "Bain-marie of the second courses" of the power distribution line Schematic diagram E1 E4 Tubular electric heater 4 S1 S4 Switch with indication 4 ХТ1 Mains block 1 23

24 Appendix 3 “Refrigerated showcase” module of the power distribution line Schematic electrical circuit “lighting” “network” S1, S2 Switch MD 36L 16A x 250 V 2 E4 Temperature controller 1 E3 Lamp LDB E2 Freon evaporator 1 E1 Refrigeration unit 1 X2 Mains socket RA A x 250 V 1 X1 3-terminal network block 16A x 250 V 24

25 Appendix 4 Module "Cold table of the power distribution line" Circuit diagram of the "network" S1 Switch MD 36L 250 V, 16 A 1 E3 Temperature controller 1 E2 Freon evaporator 1 E1 Refrigeration unit 1 X2 Mains socket RA B, 10 A 1 X1 Mains block 3-terminal 1 25

26 Appendix 5 Scheme of connecting the distribution line module to the electrical network Connection of the distribution line module to the 220 V power network is made through a 3-terminal network block located inside the module base table, according to the following scheme: The diameter of the supply wires is at least 2 mm. The total consumption of the line is up to 5.2 kW. The circuit breaker of the input shield must be designed for a rated load current of at least 25 A. 26

27 Appendix 6 “Cash Cabin” module of the power distribution line Schematic diagram E1 Earthing bolt 1 X2 Electric socket (Eurostandard) 1 X1 3-terminal block 1 Appendix 7 Module “Neutral table” of the mobile power distribution line "Eurostandard" 220 V; 16 A 1 X2 Power outlet RA B; 10 A 1 X1 Power plug "Eurostandard" 220 V; 16 A 1 E1 Earth bolt 1 27

28 Appendix 8 Module "Bain-marie" of a mobile food distribution line Schematic diagram XT1 Power plug "Eurostandard" 220 V, 16 A 1 SA1 SA2 Switch MD36L (with backlight) 3 EK2 EK4 Tubular heater 0.3 kW, 220 V 3 Е1 Ground bolt 1 28

29 Appendix 9 “Cold table” module of a mobile food distribution line Schematic diagram ХТ1 Mains plug “Eurostandard” 220 V, 16 A 1 SA1, SA2 Switches with indication MD401/L/G 1 SK1 Thermostat with handle 1 Е2 Refrigerating unit 1 Е1 Bolt grounding 1 29

30 Appendix 10 “Refrigerated showcase” module of a mobile power distribution line Schematic diagram X2 Mains plug “Eurostandard” 220 V, 16 A 1 X1 Mains block 3-terminal (polystyrene) 1 E5 Lamp 1 E4 Evaporator “LUVE” 1 E3 Thermosensor ESK Е2 Refrigeration unit 1 Е1 Earth bolt 1 S1, S2 Switch with indication MD 36L 2 30

31 8. Complete set of delivery. The scope of delivery is determined by the customer p/n Name of the supplied elements of the food distribution line Quantity (pcs.) 1 Module for cutlery and bread 1 2 Gastronorm capacity 162 x 265 x 100 mm 4 3 Module "Refrigerated showcase" 1 4 Doors of the refrigerated showcase 12 5 Grid shelves 4 6 Tray for collecting condensate 1 7 First course food warmer module 1 8 Second course food warmer module 1 9 Gastro container with lid: 530 x 325 x x 325 x x 325 x Sectional partitions 4 11 Non-stick screens 4 12 Neutral table module » 1 13 Checkout module (left or right) 1 14 Swivel module 90 (internal or external) 1 15 Cold table module 1 16 Plate warmer module 1 17 Money holder (cash register with armrest) 1 18 Sanitary glass -Sanitary protective glass Guide for trays Guide for trays Guide for trays (internal or external) 1 rotary module 23 Operation manual 1 24 Packing 1 For module "Refrigerated showcase" 25 Channel glass clamp 1 26 Protective glass 1 27 LBO lamp

32 9. Information about acceptance. Power distribution line consisting of: Designation of the modules of the power distribution line MPKh Serial number of the module MHP MPB MVB MNS MK(u) MK(with armrest) MHS MP.01 MP.02 Module for heating plates Refrigeration unit Evaporator complies specifications TU and recognized as fit for operation. Release date 200. Accepted by the Quality Control Department. m.p. ATESI, Moscow region, Lyubertsy, st. Krasnaya, d.1 t/f (495)

REFRIGERATORY DISPLAY "BOLONESE" Operation manual ATESY Refrigerated display case "Bolognese". Thank you for purchasing the showcase. We are confident that you have not wasted your money. Technical description. showcase

TECHNOLOGICAL TABLE WITH HEATING (STP-1600 coupe) Operation manual ATESY Heated technological table STP-1600 (coupe) 1. Technical description. Thank you for purchasing our product.

THERMAL DISPLAY CASE FOR KUR "Komandor" VK-4, VK-5, VK-6 Operation manual ATESY THERMAL DISPLAY CASE FOR KUR "Komandor-VK" VK-4, VK-5, VK-6 Thank you for purchasing our device. We are sure that

FISH DISPLAY "VILAMORA" Operating manual ATESY Fish display "Vilamora" Thank you for purchasing our product. We are confident that you have not wasted your money. Technical description. showcase

Roasting cabinet (series 900) ESHV 3 15/380, ESHV 2 10/380, ESHV 1 5/220 ATESY operation manual Cooking cabinet (series 900) ESHV-3-15/380, ESHV-2-10/380, ESHV -1-5/220. Thank you for purchasing our product.

GASTRONOMY LINE FOR SMALL KITCHENS (400 series) TAVERN Instruction manual ATESY Gastronomic line for small kitchens Tavern (400 series) Thank you for purchasing our line. We are sure,

FRYING BATH “CHEBURECHNICA” Operation manual ATESY Deep frying bath “Cheburechnitsa” for public catering system. Thank you for purchasing our unit. We are sure that you did not spend in vain

Roasting cabinet (series 900) ESHV 3 15/380, ESHV 2 10/380, ESHV 1 5/220 Operating manual ATESY 1 Cooking cabinet (series 900) ESHV-3-15/380, ESHV-2-10/380, ESHV-1-5/220. Thank you for purchasing our

FRYER BATH "PANDA" Instruction manual ATESY Deep fryer "Panda" for public catering system. Thank you for purchasing our unit. We are confident that you have not wasted your money.

Salamander grill GS-600/2-E ALENTA Operation manual GS.01.000.000RE rev. 00 1 Salamander electric grill GS-600/2-E ALENTA Technical description Salamander electric grill GS-600/2-E

FEEDING LINE ATESY Operation Manual Feeding Line Thank you for purchasing our line. We are confident that you have not wasted your money. Technical description. Food distribution line

TM 02 ROLLER GRILL "GRATI 5" Operating manual ATESY Roller grill for hot dogs "Grati 5" Thank you for purchasing our device. We are confident that you have not wasted your money.

FRYER BATH “PANDA-EURO” Operating manual ATESY FR.04.000.000 RE rev. 01 FR.04.000.000 RE amend. 01 2 Frying pan "Panda-Euro" for the public catering system. Thank you for your purchase

Showcase-bain-marie for burgers VMB-750/4 “Pe-1 Operation manual ATESY “Pech Thank you for purchasing our product. We are confident that you have not wasted your money. Technical description

BUILT-IN POWER DISTRIBUTION LINE "REGATA" Operation manual ATESY FK.01.000.000RE rev. 00 FK.01.000.000RE change. 00 2 Food distribution line Thank you for purchasing our line. We are sure,

FRYER BATH "PANDA-EURO" "PANDA-EURO"-E Operation manual ATESY FR.04.000.000 RE rev. 02 1 FR.04.000.000 RE change. 02 2 Frying pan "Panda-Euro" for the catering system. Thank you

PASSPORT for hot table Yekaterinburg 2010 HEAT TABLE 1. TECHNICAL DESCRIPTION The hot table is a necessary addition to the power distribution lines or can be used as a separate piece of equipment

INTEGRATED FEEDING LINE "REGATA" ATESY Operation Manual Feeding Line Thank you for purchasing our line. We are confident that you have not wasted your money. Technical description.

Frying bath "Cheburechnitsa EURO" Operation manual ATESY ChB.05.000.000 RE rev. 00 1 ChB.05.000.000 RE change. 00 2 Frying pan "Cheburechnitsa Euro" for catering system. Thank you

STERILIZER Operating manual ATESY Knife sterilizer. Thank you for purchasing our product. We are confident that you have not wasted your money. Technical description. The sterilizer is designed

TABLE WITH COOLING VOLUME "DIXON" СХ-2/1235М; STX-2/1670M STX-3/1235M; STH-3/1670M; STX-3/1680KM Operation manual ATESY STX.12.000.000 OM amend.02

KNIFE STERILIZERS STU and STU-2 Operation manual ATESY SN.01.000.000RE rev 01 2 Knife sterilizer Thank you for purchasing our product. We are confident that you have not wasted your money. Technical

FRYING BATH “CHEBURECHNICA” Operation manual ATESY ChB.03.000.000 RE rev. 02 1 ChB.03.000.000 RE change. 02 2 Frying bath "Cheburechnitsa" for the public catering system. Thank you for

VIBRATING FLOUR SCREENER “CASCADE” Operating manual ATESY 1 Vibrating flour sifter “CASCADE” Thank you for purchasing our machine. We are confident that you have not wasted your money.

RIVIERA FEEDING LINE ATESY Operation Manual 1 Riviera Feeding Line Thank you for purchasing our product. We are confident that you have not wasted your money. 1. Technical

FOOD DISTRIBUTION LINE Bella Neva 2004 food distribution line 16 Bella Neva 2004 food distribution line Designed for short-term storage ready meals and their subsequent distribution to visitors

TM02 ELECTRIC STOVE OF THE KITCHEN LINE (series 900) "TRADITION" ATESY Operation Manual Electric stove of the kitchen line "Tradition" (series 900). Thank you for purchasing our product. We

Https://m-holod.ru/brand/atesy/ Pancake station BS-15/7P Operation manual ATESY Pancake station Thank you for purchasing our product. We are confident that you have not wasted your money. 1. Technical

BATH-WASHING BATH WITH PEDAL (WITHOUT PEDAL) Operating manual ATESY ВРН1.600.000.000 RE rev. 01 1 Foot-pedal wash basin (without foot-pedal) Thank you for purchasing our unit. We are sure that

Kitchen line "TRADITION-2008" (series 900) STEAM MAIN MAIN COURSE ATESY Instruction Manual Kitchen line "Tradition-2008" (series 900) Steam mains food warmer Thank you for purchasing our

The MASTER distribution line is developed on the basis of the best European analogues. All elements are made of polished stainless steel and have an internal frame made of profiled galvanized pipe. Virtues

AU40 ROLLER GRILL GR-5/0,96-E ALENTA Operation manual GR.05.000.000RE amend. 00 1 GR.05.000.000RE change. 00 2 Roller grill for cooking hot dogs GR-5/0,96-E ALENTA Technical description.

ELECTRIC FILLING BOILER K N-20A Operating manual Electric bulk boiler KN-20A Technical description KN-20A boiler is designed for preparing boiling water at enterprises

Island ventilation umbrella (collapsible) ZVO-2000/2000, ZVO-2000/1600, ZVO-1600/1600 ATESY OPERATION MANUAL Island ventilation umbrella ZVO-2000/2000, ZVO-1600/2000, ZVO 1600/1600

KITCHEN LINE "TRADITION-2008" (series 900) STEAM MAIN COURSES Operating manual ATESY LK9.37.000.000RE rev. 00 Kitchen line "Tradition-2008" (series 900) Steam food warmer Thank you