Organoleptic methods for assessing the quality of fruit and vegetable products. Organoleptic evaluation of the quality of certain types of public catering products of mass production

GOST R 53104-2008

Group H08

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

Services Catering

METHOD OF ORGANOLEPTIC ASSESSMENT OF THE QUALITY OF PUBLIC FOOD PRODUCTS

public catering service. Method of sensory evaluation of catering products quality

OKS 67.240

OKSTU 0131

Introduction date 2010-01-01

Foreword

Goals and principles of standardization in Russian Federation established by the Federal Law of December 27, 2002 N 184-FZ "On Technical Regulation", and the rules for the application of national standards of the Russian Federation - GOST R 1.0-2004 "Standardization in the Russian Federation. Basic provisions"

About the standard

1 DESIGNED BY OPEN joint stock company"All-Russian Research Institute of Certification" (JSC "VNIIS")

2 INTRODUCED by the Technical Committee for Standardization TC 347 "Trade and Catering Services"

3 APPROVED AND INTRODUCED BY Order federal agency on technical regulation and metrology of December 18, 2008 N 513-st

4 INTRODUCED FOR THE FIRST TIME

Information about changes to this standard is published in the annually published information index "National Standards", and the text of changes and amendments - in the monthly published information indexes "National Standards". In case of revision (replacement) or cancellation of this standard, a corresponding notice will be published in the monthly published information index "National Standards". Relevant information, notification and texts are also placed in information system common use- on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

1 area of use

1 area of use

This standard applies to mass-produced catering products and establishes a method for the organoleptic evaluation of their quality.

2 Normative references

This standard uses normative references to the following standards:

GOST R ISO 3972-2005 Organoleptic analysis. Methodology. Taste sensitivity test method

GOST R ISO 5492-2005 Organoleptic analysis. Dictionary

GOST R 50763-2007 Catering services. Public catering products sold to the population. General specifications

GOST 5904-82 Confectionery products. Acceptance rules, sampling and sample preparation methods

Note - When using this standard, it is advisable to check the validity of reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annually published information index "National Standards", which was published as of January 1 of the current year , and according to the corresponding annually published information signs published in the current year. If the reference standard is replaced (modified), then when using this standard, you should be guided by the replacing (modified) standard. If the referenced standard is canceled without replacement, the provision in which the reference to it is given applies to the extent that this reference is not affected.

3 Terms and definitions

This standard uses the terms according to GOST R ISO 5492, GOST R ISO 3972, GOST R 50763, as well as the following terms with the corresponding definitions.

3.1 General terminology

3.1.1 sensory analysis: Analysis using the sense organs (highly specific receptor organs) that provide the body with information about environment with the help of sight, hearing, smell, taste, touch, vestibular reception and interoception.

3.1.2 organoleptic analysis of catering products: Sensory analysis of food service products using smell, taste, sight, touch and hearing.

3.1.3 organoleptic evaluation of the quality of catering products: Evaluation of the response of the human senses to the properties of public catering products as an object under study, determined using qualitative and quantitative methods.

3.1.4 touch specifications: The minimum acceptable quality ratings for each organoleptic characteristic of catering products, established by the manufacturer of the product and used in the quality control procedure.

3.1.5 flaw: Not full compliance of public catering products with the requirements for its quality.

3.1.6 defect: Failure to meet the specified or expected quality requirements for catering products.

NOTE Defects can be critical and/or major.

3.1.7 mass-produced catering products: Public catering products manufactured in batches.

3.1.8 batch of catering products: Any number of catering products of the same name, same date and production shift, manufactured under the same conditions at the same enterprise, in the same consumer packaging and / or the same shipping container.

3.2 Methodology terminology

3.2.1 tested sample: A sample of catering products intended for organoleptic examination.

3.2.2 tested portion: The portion of a food service item being tested that is directly evaluated.

3.2.3 scale: An ordered set of consecutive values (graphical, descriptive, or numerical, such as a score) used to represent the quality level of an organoleptic characteristic.

3.2.4 quality rating: The method that quantification quality of public catering products using ordinal (point) scales in accordance with the level overall quality products, and / or its individual organoleptic characteristics, as well as the analysis of shortcomings and defects typical for products of this type.

3.3 Terminology of organoleptic characteristics

3.3.1 appearance: An organoleptic characteristic that reflects the general visual impression or a set of visible parameters of catering products and includes such indicators as color, shape, transparency, gloss, sectional view, etc.

3.3.2 texture: Organoleptic characteristic, which is a set of mechanical, geometric and surface characteristics of food service products that are perceived by mechanical, tactile and, where possible, visual and auditory receptors.

3.3.3 consistency: A set of rheological (associated with the degree of density and viscosity) characteristics of public catering products perceived by mechanical and tactile receptors.

Note - The consistency is one of the components of the texture.

3.3.4 smell: An organoleptic characteristic perceived by the olfactory organ when volatile aromatic components of public catering products are inhaled.

3.3.5 taste: An organoleptic characteristic that reflects the sensations resulting from the interaction of various chemicals on taste buds.

4 Methodology for conducting an organoleptic assessment of the quality of mass-produced public catering products

4.1 General

Organoleptic analysis should be carried out directly at the catering establishment. The conditions and venue are determined by the management of the enterprise.

The organoleptic assessment of the quality of public catering products is carried out by employees of the enterprise.

Employees participating in the sensory evaluation should not have any restrictions for medical reasons (chronic diseases and allergies), have the skills to evaluate products and know the quality criteria.

For organoleptic analysis, tableware, cutlery and kitchen utensils are used.

Each participant in the evaluation must be provided with neutralizing products that restore taste and smell sensitivity: white wheat bread or dry unleavened biscuits, ground coffee, non-carbonated drinking water (pH - neutral, tasteless and odorless, preferably with a known hardness) and / or other products.

4.2 The method of organoleptic evaluation is intended for objective quality control of mass-produced public catering products and consists in a direct rating assessment of the quality of product samples in general and / or some key organoleptic characteristics of product samples. For each assessed characteristic, sensory specifications are established.

4.3 Organoleptic analysis of mass-produced catering products includes a rating assessment of appearance, texture (consistency), smell and taste using a point scale: 5 points - excellent quality, 4 points - good quality, 3 points - satisfactory quality and 2 points - unsatisfactory quality.

4.4 Requirements for sampling and sample preparation

Sampling for organoleptic analysis of flour confectionery carried out according to GOST 5904; culinary products- according to national standards for food products of specific types.

The quality of public catering products by organoleptic indicators is determined for the batch immediately after its manufacture, before sale.

The number of tested portions of the product should correspond to the number of employees involved in its evaluation.

When organoleptically evaluating a large range of product samples, it must be taken into account that dishes (products) with mild organoleptic characteristics (for example, cereal soups) are first tasted, then products with more intense properties are evaluated, and sweet dishes are evaluated last. The evaluation of each sample is carried out in the order of presentation without returning to previously tested samples.

In organoleptic assessment, the temperature of public catering products must correspond to the temperature of the dish (product) during their sale. The temperature of the product sample and the mouthwash should, if possible, be the same.

After evaluating each sample, employees should remove the remaining aftertaste by rinsing the mouth with water and/or using other neutralizing agents.

The results of the assessment of each product sample are drawn up in the manner established by the enterprise.

4.5 Assessment procedure

The rating assessment of the quality of catering products can be carried out both in general (general level of quality), and in terms of characteristics (for example, appearance, smell or taste) and / or individual key features(for example, color, sectional appearance, or taste).

The quantity and set of organoleptic characteristics for each type of product is determined by the management of the enterprise, depending on the objectives of quality control.

For certain groups of dishes, the number of estimated indicators can be reduced (clear soups) or increased (confectionery and bakery products). For example:

- for culinary dishes, flour confectionery and bakery products, the following characteristics can be assessed: appearance, texture (consistency), smell and taste;

- for semi-finished products - according to appearance, texture (consistency) and smell.

When evaluating the appearance, attention is paid to its specific properties, such as color (basic tone and its shades, intensity and uniformity), shape and its preservation in ready dish(product), the state of the surface, the view in the section (break), the correctness of the design of the dish, etc.

Texture (consistency) assessment is carried out:

- visually (for example, the viscosity of the liquid when poured, the density of the sauce when stirred with a spoon);

- visually and tactilely - by touching the product (product) with a cutlery (knife, fork) and / or a chef's needle, as well as by applying efforts - pressing, pressing, piercing, cutting (fish, meat products, jelly), smearing (pate, caviar , minced meat, cream);

- tactile in the oral cavity and in the process of chewing.

The odor assessment is carried out as follows: take a deep breath, hold your breath for 2-3 seconds and exhale. In the course of the analysis, the typical odor for a dish (product, semi-finished product) of this type is established, the quality of individual odor characteristics is assessed, if provided, and the presence of extraneous odors is also determined. To evaluate dishes (products) with a dense texture (consistency), for example, from meat or fish, a “needle test” or “knife test” is used, for which a wooden needle (heated knife) is inserted deep into the thickness of the product or the center of the dish, and after extracts quickly evaluate the smell.

Taste assessment is carried out as follows: the test portion of the product is placed in oral cavity, chew thoroughly and establish the typical taste for a dish (product) of this type, analyze the quality of individual taste characteristics, if provided, and also determine the presence of foreign flavors.

4.6 Establishing quality criteria

Score 5 points corresponds to dishes (products, semi-finished products) without flaws. Organoleptic indicators must strictly comply with the requirements of regulatory and technical documents.

Score 4 points corresponds to dishes (products, semi-finished products) with minor or easily eliminated shortcomings. Such shortcomings include typical for this type of product, but slightly pronounced smell and taste, uneven cut shape, insufficiently salty taste of the dish (product), etc.

Score 3 points corresponds to dishes (products, semi-finished products) with more significant drawbacks, but suitable for sale without processing. Such disadvantages include drying of the surface of products, violation of the shape, irregular shape cuts of vegetables, weak or excessive smell of spices, the presence of liquid in salads, tough texture (consistency) of meat, etc. If the taste and smell of a dish (product) is rated 3 points, then regardless of the values of other characteristics, the overall quality level is rated no higher than 3 points.

Score 2 points corresponds to dishes (products, semi-finished products) with significant defects: the presence of foreign tastes or odors, oversalted products, undercooked or undercooked, burnt, out of shape, etc.

Features of the organoleptic quality assessment certain types catering products are given in Appendix A.

In case of detection of shortcomings and / or defects in the evaluated products, the maximum possible score is reduced in accordance with the recommendations given in tables B.1 and B.2 of Appendix B.

4.7 Calculation of the product quality score

The overall assessment of the quality of the analyzed dish (product) is calculated as the arithmetic mean of the assessments of all employees participating in the assessment, accurate to the first decimal place.

Appendix A (recommended). Features of the organoleptic assessment of the quality of certain types of public catering products of mass production

A.1 Organoleptic evaluation of soups

For sampling filling soups (shchi, borscht, pickles, saltwort, etc.), the contents of the container (pot) are carefully but thoroughly mixed and poured into a plate. First, separate the liquid part with a spoon and try. The evaluation of the soup is carried out without the addition of sour cream. Then the dense part is disassembled and its composition is compared with the recipe (for example, the presence of onions, parsley, etc.). Every constituent part are examined separately, noting the ratio of liquid and solid parts, the consistency of the products, the shape of the cut, and the taste. Finally, they try the dish as a whole with the addition of sour cream, if it is provided for in the recipe.

The main indicators of the quality of clear soups are transparency, concentrated taste due to the presence of extractives (for meat and fish broths) and smell. In the organoleptic analysis of clear soups, first of all, attention is paid to the appearance of the broth, its color, the absence of suspended particles, and the glitter of fat. All side dishes for soups are tried separately, and those that are poured with broth when served are also served with it.

When assessing the quality of puree soups, the contents of the container (pot) are thoroughly mixed with a scoop and a sample of the soup is taken. Then, pouring it in a stream, evaluate the texture (consistency): density, viscosity, uniformity, as well as the presence of dense particles and color. After that, the smell is analyzed and the soup is tasted. A side dish for puree soups, which is not rubbed according to the recipe, is tried separately.

When organoleptically assessing cold soups, their appearance is evaluated and the liquid and dense parts are tried separately. The dense part is dismantled and its composition is determined, the thoroughness of cleaning, the correctness of the cut shape, the texture (consistency) of vegetables, meat products and fish products are checked. After that, they try the soup first without sour cream and then with sour cream.

A.2 Sensory evaluation of sauces

When organoleptically assessing sauces, their consistency is determined by pouring in a thin stream and tasting. Then they evaluate the color, composition (onions, cucumbers, root crops, etc.), the correctness of the cut shape, the texture (consistency) of the fillers, as well as the smell and taste.

A.3 Organoleptic evaluation of second, cold and sweet dishes (products)

Dishes and products with a dense texture (consistency) (secondary, cold, sweet), after assessing the appearance, are cut on a common plate into test portions.

A.4 Organoleptic evaluation of semi-finished products, products and dishes from boiled and fried vegetables

When checking the quality of semi-finished products, products and dishes from boiled and fried vegetables, they first evaluate the appearance: the correctness of the cut shape, and then the texture (consistency), smell and taste.

A.5 Organoleptic evaluation of semi-finished products, products and dishes from stewed and baked vegetables

When assessing the quality of semi-finished products, products and dishes from stewed and baked vegetables, vegetables and sauce are tested separately, and then the dish as a whole is tried.

A.6 Organoleptic evaluation of semi-finished products, products and dishes from cereals and pasta

When assessing the quality of semi-finished products, products and dishes from cereals and pasta, their thin layer distribute along the bottom of the plate and establish the absence of foreign inclusions, the presence of lumps. In pasta, attention is paid to their texture (consistency): boiledness and stickiness.

A.7 Organoleptic evaluation of semi-finished products, fish products and dishes

When evaluating semi-finished products, fish products and dishes, they check the correctness of cutting and compliance with the recipe; correct preparation of semi-finished products (slicing, breading); texture (consistency); smell and taste of products.

A.8 Organoleptic evaluation of semi-finished products, products and dishes from meat and poultry

At semi-finished meat products, products and dishes, first evaluate the appearance of the dish as a whole and separately of the meat product: the correctness of the cut shape, surface condition, breading. Then the degree of readiness of the products is checked by puncture with a chef's needle according to the texture (consistency) and color on the cut. After that, the smell and taste of the dish are evaluated.

For meat sauce dishes, all its components (main product, sauce, side dish) are separately evaluated, and then the dish as a whole is tried.

A.9 Organoleptic evaluation of cold dishes, semi-finished salads and snacks

When evaluating cold dishes, semi-finished salads and snacks, special attention is paid to the appearance of the dish: the correct form of cutting the main products; their texture (consistency).

A.10 Organoleptic evaluation of sweet dishes (desserts)

When evaluating sweet dishes, their group characteristics are taken into account. For jellied dishes, mousses and creams, first determine the surface condition, the appearance of the cut (break) and color. In addition, the ability to keep the shape in the finished dish is evaluated. Particular attention is paid to the texture (consistency). Then evaluate the smell and taste.

When evaluating sweet hot dishes (soufflés, puddings, croutons, hot desserts, etc.), the appearance is first examined: the nature of the surface, the color and condition of the crust; mass on the cut (break): baked, no hardening. Then evaluate the smell and taste.

A.11 Organoleptic evaluation of flour culinary semi-finished products and products

When evaluating flour dishes and flour semi-finished products and culinary products, their appearance is examined (the nature of the surface of the dough, the color and condition of the crust of pancakes, pancakes, pies, etc., the shape of the product), pay attention to the ratio of minced meat and dough, the quality of minced meat (its juiciness , degree of readiness, composition), and then evaluate the smell and taste.

A.12 Organoleptic evaluation of flour confectionery and bakery semi-finished products and products

When characterizing the appearance of flour confectionery and bakery semi-finished products and products, attention is paid to the surface condition, its finish, color and condition of the crust, the absence of peeling of the crust from the crumb, the thickness and shape of the products. Then evaluate the state of the crumb: baked, no signs of non-mixing, the nature of porosity, elasticity, freshness, lack of hardening. After that, the quality of the finishing semi-finished products is evaluated according to the following criteria: the state of the cream mass, lipstick, jelly, glaze, their splendor, plasticity. Next, evaluate the smell and taste of the product as a whole.

Appendix B (recommended). Decrease in the scoring of quality indicators of public catering products for detected defects

Table B.1 - Reduction scoring indicators of the quality of dishes and culinary products for detected defects

Disadvantages and defects | ||

APPEARANCE | ||

Decor | Careless design of the dish, the presence of sauce and dressing on the edges of the dish (if this is not provided for by the serving) | |

The absence of some finishing semi-finished products provided for by the recipe | ||

Non-observance of the ratio of the main components in the dish, provided for by the recipe, discrepancy between the set of dish components and the recipe | ||

The heterogeneity of the form of cutting components in dishes (salads, vinaigrettes, soups, vegetable stews, etc.) | ||

Shape mismatch (for molded products) with no weight change | ||

Shape mismatch (for molded products) resulting in weight change | ||

Sweet dishes (mousses, sambuca, creams, jelly, whipped cream, soufflé), aspic dishes do not hold their shape | ||

Surface condition | Violation of the integrity of products baked in the form | |

Weak drying of the surface of the main product or product | ||

Weak drying (winding) of finishing semi-finished products | ||

Lack of shine from oil on the surface of salads, vinaigrettes, milk soups, cereals | ||

The presence of a film on the surface: | ||

kissels, puree soups | ||

sauces, dressings | ||

tea leaves | ||

The presence of cracks on the surface of products baked in the mold | ||

Minor breach of shell integrity flour products, which did not lead to the outflow of minced meat | ||

Violation of the integrity of the shell of flour products with exposure and leakage of minced meat | ||

Slight peeling of the crust on fried breaded products, casseroles | ||

Separation of the crust from fried breaded products, casseroles | ||

Uniformity | The presence of sediment in fruit and berry soft drinks more than 1/5 of the volume | |

The presence of suspended particles, turbidity of jelly, broths | ||

Liquid detachment in fresh vegetable salads | ||

Separation of liquid in salads from salted, pickled vegetables, vegetable caviar more than 1/3 of the volume | ||

Significant detachment of liquid in salads from fresh, salted and pickled vegetables | ||

Foaming kissels, drinks, curdled milk, fermented baked milk, kefir and other fermented milk drinks | ||

The presence of non-mixing in products from cutlet mass, casseroles, puddings | ||

Products are poorly fried, there are traces of hardening in dough products | ||

The presence of more than 5% crumbs of the main product in dishes from natural fish and meat gastronomic products | ||

The presence of bones in meat and fish jellies | ||

The presence of single lumps of brewed flour, starch, semolina in sauces, cereals, mashed soups, kissels, pancakes | ||

The presence of lumps of brewed flour, starch, semolina in sauces, cereals, mashed soups, kissels, pancakes | ||

The presence of single sticky lumps in dishes and side dishes from cereals and pasta | ||

The presence of sticky lumps in dishes and side dishes from cereals and pasta | ||

A solid sticky mass in cereals, side dishes from cereals, pasta | ||

The presence of foreign inclusions in dishes, products | ||

Section view (fault) | The presence of a dense layer of unwhipped jelly in sweet dishes (mousses, sambuca) | |

Color (including cut) | Slightly different from typical | |

Fried or baked products are slightly colored or have intensely colored inclusions on the surface | ||

Products burnt, dark-colored or with an atypical color for these products, dishes or individual components | ||

TEXTURE (consistency) | Soft in salads of fresh, salted and pickled vegetables | |

Very tough in radish, radish salads | ||

Ointment for crumbly cereals, side dishes of cereals and pasta, casseroles, puddings, soufflés | ||

Very liquid, the ratio of dense and liquid parts is violated (in sauces, soups, compotes) | ||

Kroshlivaya in fried and baked minced products (meat, fish), cottage cheese products | ||

Dry, hard in portioned products from meat, meat products, poultry, game, rabbit, fish | ||

Crumbly or buttery in minced meat and fish; dense - in curd and vegetable; liquid - in fruit | ||

SMELL | Weak, not typical enough, with a noticeable predominance of one component | |

atypical, outsider | ||

TASTE | Weak, no taste of spices | |

Slightly oversalted | ||

Atypical, foreign, extremely spicy, salty, sour, foreign |

Table B.2 - Reducing the scoring of quality indicators of baked and finishing semi-finished products, flour confectionery and bakery products

Name of organoleptic characteristics | Disadvantages and defects | Decrease in points for mass-produced products |

APPEARANCE | Slightly deformed baked semi-finished products and products | |

The shape of the products is irregular, with slight breaks, uneven cut | ||

Baked and finishing semi-finished products with significant breaks | ||

Baked semi-finished products, products with large cracks, depressions, swellings | ||

The pattern of products, finishing semi-finished products (creams, soufflés, lipsticks) is very vague, not pronounced, smeared | ||

Baked semi-finished products, products (cakes, rolls, rich bakery products) with uneven and insufficient rise | ||

Surface condition | The upper crust of baked semi-finished products, products: | |

rough, matte, wet | ||

with pollution | ||

Finishing semi-finished products in cakes and pastries are unevenly distributed | ||

Finishing semi-finished products (pomade, glaze) lag behind the surface of products | ||

Chocolate glaze turned gray; fondant glaze sticky, candied | ||

The icing is partially chipped off the product | ||

Fondant icing with spots | ||

Jelly opaque | ||

The height of the baked semi-finished product or product is insufficient | ||

Sectional view | The top or bottom crust of the product is too thick | |

Slight lag of the upper crust from the baked semi-finished product, product | ||

The thickness of the top or bottom crust is uneven | ||

The presence of lumps, voids, traces of unmixed | ||

Weak layering, thick non-separating layers of puff cakes, pastries | ||

Finishing semi-finished products (filling, minced meat) are unevenly distributed between the layers of baked semi-finished products, products or protrude significantly beyond the edges | ||

Biscuit cakes and pastries, rolls, rum baba heavily soaked in syrup (wet) | ||

state of the crumb | The porosity of the crumb is uneven, insufficient | |

Significant crumb compaction | ||

The presence of voids, hardening, lumps, traces of unmixed | ||

The crumb is dry, hard, crumbly | ||

The color of the top crust, the surface of the products, the crumb is uneven | ||

The color of products, baked semi-finished products, top crust and crumb is pale, dark, burnt | ||

Products, crumb of an atypical color with extraneous shades | ||

Very bright color | ||

SMELL AND TASTE | Baked semi-finished products, rich bakery products with an extraneous taste of soda (ammonium); lipstick - essences; syrup - burnt sugar | |

Baked semi-finished products, rich bakery products with an extraneous intense taste of soda (ammonium); lipstick - essences; syrup - burnt sugar | ||

The presence of foreign odors, atypical for products, semi-finished products | ||

The presence of foreign smell and taste of stale products | ||

Lack of smell and taste of individual components | ||

The presence of a crunch from mineral impurities in rich bakery products | ||

Atypical, insufficiently expressed smell and taste | ||

Sour taste in rich baked goods | ||

TEXTURE (consistency) | Baked semi-finished products: | |

biscuit - dense | ||

sandy - dense not crumbly | ||

puff - stiff, slightly stretchy | ||

airy - viscous, without crumbly friability | ||

almond-nut - dry, hard, dense | ||

Baked semi-finished products and stale products; crumb dry, hard, crumbly | ||

Baked semi-finished products and unbaked products; the crumb is moist, sticky | ||

Unstable texture (consistency) jelly, soufflé | ||

Protein cream - dense, highly viscous or weak with lumps; creamy cream - dense or very weak with separated moisture, curdled with grains; lipstick - sticky | ||

Soak syrup, fruit filling - liquid | ||

Products with temper |

Bibliography

A.M., Civille, G.Y., & Carr, W.T. (1992). Sensory evaluation in quality control. New York: Yan Nostrand Reinhold, 236 |

|

MC ISO 8402 Quality Management and Quality Assurance. Dictionary |

|

MU N 1-40/3805 dated 11/11/1991 Guidelines on laboratory quality control of public catering products. Sampling procedure |

Electronic text of the document

prepared by CJSC "Kodeks" and checked against:

official publication

M.: Standartinform, 2009

General classification of fruit and vegetable products. A homogeneous group of fruit and vegetable products is divided into subgroups of four levels for fresh fruits and vegetables, into subgroups of three levels for processed fruits and vegetables according to the following classification criteria: according to the condition of tissues (fresh fruits), according to the type of main raw material (processed), according to the nature of the edible organ (fresh vegetables), processing methods and industrial processing methods (processed), by structure.

The determining properties of nutritional value are, as a rule, low energy and high physiological value, as well as unique organoleptic properties that create consumer preferences for this group. The energy value of most fresh fruits and vegetables is low (10-100 kcal/100g). The only exceptions are nuts (600-750 kcal / 100g), dates (281), olives (400-700) avocados (230-400) canned snacks (100-200 kcal / 100g) due to the increased fat content, and for nuts and squirrel. Low energy value is an advantage of fruits and vegetables, as many other groups food products differ in medium and high calorie content. Therefore, the presence of low-calorie, but physiologically complete foods is very important in the diet. In addition, it should be taken into account that every day a person consumes 300-500 g of fruits and vegetables, and sometimes more. At the expense of fruit and vegetable products, approximately 10% of the daily energy requirement of an adult human body is satisfied. Starch provides the energy value mainly in potatoes and leguminous vegetables due to its higher content compared to other types of vegetables. So, potatoes contain 10-25% starch (on average 12.5%), sweet corn - 10%, green peas - 6%, while in other types of vegetables starch is either completely absent (vegetable greens, beets, tomatoes and pumpkin vegetables), or its content does not exceed 0.1 - 1.5%. Along with carbohydrates, the energy value of fruits and vegetables is also determined by organic acids. Moreover, fresh fruits and vegetables are dominated by apple (seed-bearing, stone fruits), lemon (citrus fruits, many tropical and subtropical, berries), wine (grapes), oxalic (sorrel, rhubarb). The fat content in many types of fresh fruits and vegetables does not exceed 0.1 - 0.3%. Only in walnuts, the energy value is determined by the fat content, since its amount reaches 45-70%. At the same time, walnuts and hazelnuts are distinguished by the highest fat content, approaching in this indicator to butter and margarine with a fat content of 72%. In addition to nut fruits, olives are characterized by a high fat content - 50-75%, avocados - 2-30 (on average 23.5%), sea buckthorn - 8, legumes - 2-4%. According to the energy value, all fruits and vegetables can be divided into four groups:

1. High-calorie (EC 250-660 kcal), which include dates, olives, avocados, canned snacks, dried mushrooms.

2. Medium-calorie (EC 60-100 kcal) - potatoes, grapes, bananas, apricots, persimmons, fresh rose hips.

3. Low-calorie (EC 30-59 kcal) - most of the subgroups of fresh fruits and vegetables, except for those included in other groups.

4. Super-low-calorie (EC - 10-29 kcal) - lettuce-spinach, spicy-tasting, cucumbers, zucchini, pumpkin, tomatoes.

In contrast to the commercial classification, which subdivides fruit and vegetable products into fruits, nuts, potatoes, vegetables and gourds, mushrooms, commodity classification more details the defining features of individual subgroups and has general principles construction, although sometimes there are exceptions to it. Commodity classification does not completely coincide with the botanical one, despite borrowing from the latter one of the defining features - the structure of plant organs used for food. The defining features of the commodity classification of fresh fruits and vegetables are the purpose, the commonality of the anatomical structure and the specificity of the composition. Thus, the principle of commodity classification is based on a set of defining features. Fresh vegetables are divided into two groups of 3 stages according to the nature of the organ used: vegetative (tubers, root vegetables, cabbage, onion, lettuce-spinach, spicy-tasting, dessert vegetables) and fruit (pumpkin , tomato and legumes) vegetables. In foreign literature, a subgroup of exotic vegetables is distinguished, which include artichokes, some salad and spicy-tasting vegetables (fennel, escariole, chicory salad, etc.). In addition, another feature is used in the classification of fruits and vegetables - the growing condition. In accordance with it, fruits, vegetables and mushrooms can be divided into cultivated, grown specifically for consumption, and wild, growing independently and collected for use for food, technical or pharmaceutical purposes. Fresh vegetables are divided into two subgroups: vegetative and fruit vegetables.

1. Vegetative vegetables:

tubers - types: potatoes, Jerusalem artichoke, sweet potato;

root crops - like carrots: carrots, parsley, celery, parsnips; beet type: table beet; type of radish: radish, radish, turnip, swede;

cabbage vegetables - subgroups: pumped: white cabbage, red cabbage, Brussels sprouts, Savoy; flower: color, broccoli; stem-bearing: kohlrabi.

onion vegetables - subgroups: onion - onion, garlic; green onions - leek, batun, slime, shallot, wild garlic, chives, multi-tiered.

lettuce-spinach vegetables - groups: unleavened salads - leaf, head lettuce, romaine lettuce, Beijing lettuce; bitter salads - witloof, endive, escarole, watercress, mustard leaf; spinach - sorrel, spinach, chard, nettle, etc.

spicy-tasting vegetables - subgroups: rhizomatous - horseradish, katran; leafy - dill, fennel, coriander, tarragon, mint, lemon balm, savory, basil, marjoram, etc.

dessert vegetables - types: rhubarb, asparagus, artichoke

2. Fruit vegetables:

pumpkin vegetables - types: pumpkins, zucchini, squash, cucumbers, watermelons, melons;

tomato vegetables - types: tomatoes, eggplants, sweet peppers;

leguminous vegetables - cereal subgroups: sweet corn; legumes: green peas, beans, beans.

The biological value of fruits and vegetables is low due to the low protein content. However, the proteins of many types of fruits and vegetables are complete (potatoes, cabbage vegetables, nuts, legumes, mushrooms) and serve as an addition to the animal proteins of the daily diet.

Biological efficiency characteristic only for nuts, olives, avocados, sea buckthorn, legumes. Moreover, the fat of many of these species is rich in polyunsaturated fatty acids. All other types of fresh fruits and vegetables are not biologically effective.

Physiological value fruit and vegetable products is due to physiologically active substances (β - carotene, inositol, tartaronic acid, vitamin U, etc.); pectin, phenolic, coloring, aromatic substances, phytoncides and phytoalexins. In addition, fruits and vegetables contain ballast substances: cellulose, hemicelluloses, etc., which, together with pectin substances, form plant dietary fibers and contribute to the removal of harmful substances, including radionuclides, from the human body. vitamin value fruit and vegetable products are associated primarily with vitamin C, since fresh fruits and vegetables, as well as their processed products, which include juices, are the only source of ascorbic acid for humans. This vitamin is absent in grain flour, meat and fish products. A small amount of vitamin C is found in milk and some processed products, as well as in fortified foods. However, dairy products are not of great importance for meeting the need for vitamin C. The content of vitamin C in fruits and vegetables, as well as processed products, ranges from 5 to 1200 mg%. The richest in vitamin C are fresh and dry rose hips, black currants, and vegetable peppers (200-1200 mg%). Citrus fruits, strawberries, kiwi, cabbage, lettuce-spinach and spicy-tasting vegetables differ in the average content of the vitamin (40-150 mg%), and other types are low. During the processing of fruits and vegetables, especially in traditional types of drying and canning, vitamin C is largely destroyed. Freezing, pickling, freeze-drying contribute to better preservation of vitamin C. The second most important in the diet is vitamin P, which, as a rule, is more abundant in fruits, especially those rich in vitamin C and having an astringent taste and / or red color. Compared to fruits, vegetables are poorer in vitamin P. An exception is vegetable peppers, which are high in vitamins C and P. Blackcurrant stands out among fruits with a high content of P. Folic acid (B 9) is rich in leafy vegetables and strawberries, especially wild strawberries. In addition to these vitamins, many fruits and vegetables are an important source of such vitamin-like substances as β-carotene, inositol (green peas, orange), tartaronic acid (most species), vitamin U (in cabbage vegetables, radish). β-carotene - provitamin A is found in significant amounts in yellow or orange-colored fruits and vegetables (sea buckthorn, apricot, peaches, carrots, pumpkin, zucchini) and less in green leafy vegetables (parsley, celery, lettuce, etc.). The vitamin value of fresh fruits and vegetables is higher than processed ones, since vitamins are destroyed during processing, especially during sterilization and drying. Mineral value fresh and processed fruits and vegetables is about the same. Only in pickled vegetables does the mineral composition change greatly due to osmosis. table salt, resulting in an increase in the content of sodium, chlorine and a small amount of potassium, magnesium and calcium. The most important element of the mineral composition of most fruit and vegetable products is potassium (approximately 50% of the total), followed by magnesium (especially in green-colored fruits and vegetables), sodium, calcium, iron (the elements are arranged in descending order). Apricots, peaches, grapes, apples, porcini mushrooms are rich in iron. Of the other elements, fruits and vegetables contain sulfur (cabbage vegetables, radishes and radishes differ in an increased amount), boron, manganese, iodine (it is abundant in feijoa, as well as fruits and vegetables grown in coastal areas). The total number of elements in fruit and vegetable products exceeds 60. Due to the consumption of fruit and vegetable products within physiological norms, up to 50% of a person's daily need for potassium and up to 30% for magnesium is satisfied. The share of other elements in meeting the daily requirement is much less.

Physiological value fruits and vegetables is also due to phenolic compounds: catechins and tannins, called tannins and giving the product an astringent taste; anthocyanins and flavones, which cause red, blue, purple, golden color of different shades; coumarins and furrocoumarins, phenolic acids. Many of these substances have P - vitamin activity, bactericidal and other useful properties. Therefore, fruits and vegetables are also used in clinical nutrition. A special place among physiologically active substances is occupied by phytoncides and phytoalexins, which, having a bactericidal ability, determine the medicinal properties of fruits and vegetables, and also form natural resistance against microorganisms. Phytoncides are organic compounds that can suppress or kill pathogenic microorganisms. In the tissues of fruits and vegetables, they are always present and are products of their normal life. Phytoncides are essential oils onions, garlic, citrus fruits, mustard, horseradish, radish; phenolic, some organic and other compounds. Phytoalexins are antibiotics of plant origin. In the intact tissue of fruits and vegetables, they are present or present in negligible amounts. When damaged, their biosynthesis occurs. By chemical nature, they most often belong to terpenes. Phytoalexins cause uncoupling of the processes of respiration and phosphorylation, inhibit the biosynthesis of nucleic acids and proteins, increase the permeability of cell membranes both in the cell of the microorganism and in the host plant, which ultimately causes the death of both organisms.

Organoleptic value of fruits and vegetables, especially fresh ones, is due to their beautiful appearance: graceful shape, various basic and outer color, glossy or matte surface, unique taste and aroma, specific for each species, and sometimes varieties, delicate juicy or dense crispy texture, characteristic internal structure. These organoleptic indicators simultaneously perform the function of identifying the type and variety of signs of fruits and vegetables. Digestibility of fruits and vegetables depends on the amount of cell juice containing easily digestible soluble substances, as well as ballast carbohydrates. The more of the latter, the lower the digestibility of fruits and vegetables. The digestibility of fresh fruits and vegetables is affected by the condition of the tissues of the skin and pulp. In immature fruits and vegetables, the cell walls contain a lot of fiber and protopectin, so the cell sap is less available in them than in mature ones. Processed fruits and vegetables are digested better than fresh ones, since cells die during processing, and digestible substances are partially destroyed.

Fruit and vegetable safety according to SanPin 2.3.2.1078-01, it is normalized according to general indicators: toxic elements (arsenic, mercury, lead, cadmium), radionuclides, nitrates, microbiological indicators (the number of mesophilic aerobic and facultative anaerobic microorganisms, bacteria of the Escherichia coli group, pathogenic microorganisms, including including salmonella, yeast, mold). In addition to these, specific indicators are provided: - in nuts - the maximum permissible level of mycotoxin aflatoxin B 1;

Features of assessing the quality of fresh fruits: assessment the quality of fresh fruits is carried out according to safety performance And commercial quality indicators, regulated by standards or other normative documentation. The safety of fresh fruits is determined by indicators such as toxic elements, pesticides, mycotoxins and radionuclides.

According to SanPiN 2.3.2.1078-01, the following permissible levels are established for fresh fruits. The content of toxic elements (mg/kg, no more): lead -0.4; arsenic - 0.2; cadmium - 0.03; mercury - 0.02; pesticide, such as isomers of hexachlorocyclohexane - 0.05. The main mycotoxin determined for fresh fruits is patulin, except for nuts, for which aflatoxin B is determined - the permissible level of the latter is not more than 0.005. The radiation safety of fresh fruit is confirmed by its compliance with the permissible levels of specific activity of radionuclides (Bq/kg): cesium-137 - 40; strontium-90 - 30; for wild berries - 160 and 60, respectively; for nuts - 200 and 100, respectively.

The main general indicators of the commercial quality of fresh fruits include: appearance, size (size), smell, taste and tolerances. Appearance- a complex indicator of fresh fruits, including single indicators: freshness, integrity, color, shape, surface condition, maturity. Freshness- one of the most important indicators quality, which depends on the density of tissues, skin and pulp, the degree of ripeness of the fruit. The exception is nuts, in which this indicator is not standardized. Fresh fruit must be unwilted. Size fresh fruits are determined by their largest transverse diameter, and hazelnuts - by weight. The size is not standardized for some types of fruits (plums, cherry plums and apples of small-fruited varieties, apricots and cherries of the 2nd grade, as well as for most berries; the exception is strawberries of the 1st grade. Smell And taste - the most significant organoleptic indicators, they are characterized as characteristic of this botanical variety, without the presence of foreign smell and taste. Permissible deviations are established by the standards for each type of fruit according to the following indicators: freshness, integrity, shape, surface condition and size. Permissible deviations are understood as deviations of the actual value of the fruit quality indicator from the nominal value within the limits regulated by the standards.

Common tolerances for most fresh fruits are pest damage and mechanical damage. The latter are classified into minor (abrasions, scratches), significant (pressure, hailstones, punctures, cracks, etc.) and critical (crushing). They worsen the appearance of fresh fruits, reduce their resistance to phytopathogenic microorganisms, and cause an increase in storage losses. Most fresh fruits (from berries - only strawberries, maliu and grapes) are divided into commercial varieties. Apples and pears of summer and early autumn varieties, harvested before September 1, are divided by quality into the 1st and 2nd commercial varieties, evaluating them according to standards for products of early ripening. The quality of apples and pears harvested after September 1 is assessed as late ripening and divided into four commercial varieties: the highest, 1st, 2nd and 3rd. General requirements for the quality of apples and pears of any ripening period: the fruits must be of the form characteristic of the pomological variety, fresh, whole, healthy, clean, without foreign smell and taste, certain sizes and degree of maturity . Permissible deviations in the number of pressures, the area of abrasions, hailstones and punctures, dots, scab spots, codling moth damage, subcutaneous spotting, browning of the skin and pulp are different depending on the ripening time and commercial grade of the fruit. The highest late-ripening apples and pears can be isolated only from pomological varieties of the first pomological group. Late ripening apples and pears related to To 3rd grade, according to current standards, should not be stored for long-term storage, but can be used for industrial processing or immediate sale. According to the requirements given in all standards for pome fruits, fruits affected by fruit, black, blue or other rot, as well as overripe and with the presence of physiological diseases, such as plumpness, severe browning of the pulp, wet burn, severe wilting, freezing. Fresh by standards apricots, cherries, sweet cherries, plums And large-fruited cherry plum depending on the quality, they are divided into the 1st and 2nd commercial grades, and fresh peaches- for three commercial varieties: the highest (only high-value pomological varieties of the first pomological group), 1st and 2nd. Fresh dogwood And cherry plum small-fruited is not divided into commercial varieties.

General requirements for the quality of stone fruits- appearance (shape, color typical for the pomological variety), size according to the largest transverse diameter, degree of maturity and permissible deviations (presence of fruits with healed lesions, brown pressure spots, without stalk, overripe). Decayed and green stone fruits are not allowed. Most often, fruits are damaged by such microbiological diseases as gray fruit rot and clasterosporiasis, as well as pests - plum codling moth and weevil.

Ampelographic varieties grapes subdivided into the first, second and third groups, the lists of which are given in the appendix of the standard. By quality, the grapes of each group are divided into the 1st and 2nd commercial varieties. When checking the quality of grapes and establishing a commercial variety, the terms of transportation of consignments are taken into account - shipped before November 1 and after November 1. General requirements for standard grapes include a description of the appearance of clusters and berries, which must be whole, normally developed, healthy, clean, ripe, without excessive moisture, foreign smell and taste. Mass fraction sugar in berries (at least 12, 14 and 15%) is normalized depending on the growing area and variety group. In standard batches, a certain number of incomplete clusters of berries are allowed at destinations - cracked, crumbling and pea, rotten and crushed. At the same time, the terms of acceptance of products (before or after November 1) are taken into account. When sold in retail trading network there should be no rotten and crushed berries. Grapes are most often affected by diseases: gray rot, oidium, downy mildew, anthracnose.

Quality according to standards gooseberry And currant are not classified into commercial grades. The requirements for their appearance are the same: the berries must be fresh, clean, dry, uniform in degree of maturity, of the same pomological variety, without damage by pests and diseases. In standard batches of gooseberries, defects are allowed - the presence a certain amount berries of other pomological varieties and slightly damaged by powdery mildew are regulated without taking into account the place of use. The allowable amount of overripe and mechanically damaged berries is standardized separately for harvesting sites and for destinations. For blackcurrant, the permissible deviations are established by the standard, taking into account the method of picking berries (without brushes or in brushes), the place of harvest or destination according to the following indicators: berries that have not reached normal color, but not green, crushed and separated from the brushes (for batches with berries in hands). General quality indicators cranberries And lingonberries: berries are clean, fresh (cranberries can be frozen), heterogeneous in size and color (from pink to red - lingonberries and dark red - cranberries), without damage and diseases, foreign smell and taste. Berries may be wet, but should not run. Permissible defects in cranberries are normalized taking into account the time of harvesting berries (autumn or spring) and the place of quality determination (when harvesting or selling): the percentage of unripe, mechanically damaged and dried berries, as well as impurities of edible berries of other species and plant particles such as twigs, leaves, moss, stalks. Green cranberries, inedible berries (such as nightshade), sand and other contaminants are not allowed. At destinations, the standard allows no more than 4% of moldy and rotten berries. In standard batches of lingonberries, no more than 1% of unripe and 1% of overripe berries are allowed; admixtures of edible berries of other species and plant particles (leaves, moss) are also limited.

For nuts hazel the weight of 100 pieces is normalized: 1st grade - not less than 100 g; 2nd - 60 g. The output of the hazel kernel of the 1st grade should be at least 45%, the 2nd - 35%. In the 2nd grade, deviations in form and maturity are allowed; kernels can be shriveled, rancid, moldy, damaged by pests, with an admixture of litter (from 0.3 to 3%). For all varieties of nuts, the moisture content of the kernel is normalized (%, not more than): hazel - 15; hazelnuts - 14. The quality of shelled hazelnut kernels used for processing is evaluated according to a separate standard, according to which the kernel is divided by quality into the highest and 1st grade. Permissible humidity of hazelnut kernels - 6%.

Walnuts subdivided according to quality into the highest, 1st and 2nd commercial grades. When assessing the quality, the appearance, color and quality of the shell, the taste and smell of the kernel, as well as its color, quality at the break are taken into account. The size of the nut by the largest transverse diameter (mm, not less than): the highest grade - 28; 1st - 25; 2nd - 20; walnut surface: the highest and 1st grade - smooth; 2nd - rough. The output of the kernel must be (% mass, not less than): the highest grade -50; 1st -45; 2nd - 35%. The moisture content of the core is normalized: regardless of the variety, it should not exceed 10%. Foreign impurities, shells, fruits with dried shells, damaged by pests, rancid and underdeveloped are allowed mainly for the 1st and 2nd grades in limited sizes. The quality of sweet nuts almond divided into the highest and 1st commercial grades. Hard shell nuts can only be of the 1st grade if they have a kernel yield of at least 25%, nuts of the other three groups are classified as the highest grade with a kernel yield of at least 30% and meet the other requirements of the standard. If the nuts of the three groups listed above do not correspond to the standard indicators of the highest grade, then they are referred to the 1st grade, taking into account the restrictive norms of such permissible defects as the presence of dried peel, rancid and moldy kernels, clogging of the shell, damage by pests.

Vegetables and fruits are important suppliers of potassium and many trace elements. The most rich in potassium are dried fruits, potatoes, green peas, tomatoes, beets, radishes, green onions, cherries, currants, grapes, apricots, peaches. Vegetables and fruits contain much more potassium than sodium, so they are especially important in diets with sodium restriction and increased potassium: hypertension, circulatory failure, kidney disease, etc. Vegetables and fruits are poor in calcium, phosphorus, sodium, and only some of them serve as a good source of magnesium - dried fruits, lettuce, beets, carrots, green peas, black currants, cherries. Vegetables and fruits have "alkalinizing" properties, which has great importance with circulatory failure, kidney, liver, febrile conditions, diabetes, etc. They contain a lot of water (75 - 95%).

Due to the mineral composition of vegetables and fruits, water quickly leaves the body, facilitating the excretion of metabolic products. The diuretic (diuretic) effect of vegetables and fruits is especially important in diets with circulatory failure, kidney, liver, and gout.

Quality indicators fruits and vegetables are divided into general and specific. General quality indicators include appearance, size and tolerances in size and quality.

He considers maturity or ripeness, internal structure, taste, density, underdevelopment or maturity of seeds, and some others as specific indicators of the quality of fruits and vegetables.

When assessing the quality of fresh fruits and vegetables, chemical indicators are not taken into account. Particular attention is paid to the appearance and size of fruits and vegetables. Appearance includes the following properties of vegetables: shape, color, maturity, freshness, integrity, contamination, damage by mechanical and agricultural pests. The form should be typical for each economic-botanical, pomological, ampelographic variety. Fruits and vegetables of an ugly shape are not allowed.

Coloring determines the dignity of the appearance and maturity of fruits and vegetables. Distinguish between the main and integumentary color. The main color can be green, yellow, orange, and the cover color can be red and purple. Brightly colored fruits and vegetables are most highly valued. Maturity is also associated with the internal structure, chemical composition, consumer advantages and keeping quality of fruits and vegetables. The fruits should be uniform in maturity, but not green and unripe.

All fruits must be fresh and juicy. Weak wilting is allowed in a limited amount in some fruits (in late 1st grade apples).

Integrity characterizes the degree of damage to individual specimens of fruits, the presence of cuts, scratches, spots from bruises and other mechanical damage or damage by agricultural pests on their surface, as well as the defeat of phytopathological and physiological diseases.

The size of most fresh fruits is determined by the largest transverse diameter. Standards usually provide lower limits for the size of fruits (in mm or cm, no less).

Fruit defects include damage by mechanical and agricultural pests, microbiological and physiological.

Mechanical damage worsens the appearance of fruits, facilitates access to their tissues of microorganisms, increases the intensity of respiration and evaporation of moisture during storage.

Damage caused by agricultural pests includes, for example, damage to apples, pears, plums - codling moths, apricots, apples - goose.

Fruits affected by many pests are usually rejected, as their presentation deteriorates significantly, and nutritional value decreases.

Organoleptic evaluation of soups

For sampling filling soups (shchi, borscht, pickles, saltwort, etc.), the contents of the container (pot) are carefully but thoroughly mixed and poured into a plate. First, separate the liquid part with a spoon and try. The evaluation of the soup is carried out without the addition of sour cream. Then the dense part is disassembled and its composition is compared with the recipe (the presence of onions, parsley, etc.). Each component is examined separately, noting the ratio of the liquid and solid parts, the consistency of the products, the shape of the cut, and the taste. Finally, they try the dish as a whole with the addition of sour cream, if it is provided for in the recipe.The main indicators of the quality of clear soups are transparency, concentrated taste due to the presence of extractives (for meat and fish broths), and smell. In the organoleptic analysis of clear soups, first of all, attention is paid to the appearance of the broth, its color, the absence of suspended particles, and the glitter of fat. All side dishes for soups are tried separately, and those that are poured with broth when served are also served with it.

When assessing the quality of puree soups, the contents of the container (pot) are thoroughly mixed and a sample of the soup is taken. Then, pouring it in a stream, evaluate the texture (consistency): density, viscosity, uniformity, as well as the presence of dense particles and color. After that, the smell is analyzed and the soup is tasted. A side dish for puree soups, which is not rubbed according to the recipe, is tried separately.

When organoleptically assessing cold soups, their appearance is evaluated and the liquid and dense parts are tried separately. The dense part is disassembled and its composition is determined, the thoroughness of cleaning, the shape of the cut, the texture (consistency) of vegetables, meat products and fish products are checked. After that, they try the soup first without sour cream and then with sour cream.

Organoleptic evaluation of sauces

When organoleptically assessing sauces, their consistency is determined by pouring in a thin stream and tasting. Then they evaluate the color, composition (onions, cucumbers, root crops, etc.), the shape of the cut, the texture (consistency) of the fillers, as well as the smell and taste.Organoleptic evaluation of the second, cold and sweet dishes (products)

Dishes and products with a dense texture (consistency) (secondary, cold, sweet), after assessing the appearance, are cut on a common plate into test portions.Organoleptic evaluation of semi-finished products, products and dishes from boiled and fried vegetables

When checking the quality of semi-finished products, products and dishes from boiled and fried vegetables, they first evaluate the appearance: the correctness of the cut, and then the texture (consistency), smell and taste.Organoleptic evaluation of semi-finished products, products and dishes from stewed and baked vegetables

When assessing the quality of semi-finished products, products and dishes from stewed and baked vegetables, vegetables and sauce are tested separately, and then the dish as a whole is tried.Organoleptic evaluation of semi-finished products, products and dishes from cereals and pasta

When assessing the quality of semi-finished products, products and dishes from cereals and pasta, they are distributed in a thin layer along the bottom of the plate and the absence of foreign inclusions, the presence of lumps is established. In pasta, attention is paid to their texture (consistency): boiledness and stickiness.Organoleptic evaluation of semi-finished products, fish products and dishes

When evaluating semi-finished products, fish products and dishes, they check the correctness of cutting and compliance with the recipe, the correct preparation of semi-finished products (cutting, breading), texture (consistency); smell and taste of products.Organoleptic evaluation of semi-finished products, products and dishes from meat and poultry

For semi-finished meat products, products and dishes, first evaluate the appearance of the dish as a whole and separately - the main product: the shape of the cut, surface condition, breading. Then the degree of readiness of the products is checked by puncture with a chef's needle according to the texture (consistency) and color on the cut. After that, the smell and taste of the dish are evaluated.For meat sauce dishes, all its components (main product, sauce, side dish) are separately evaluated, and then the dish as a whole is tried.

Organoleptic evaluation of cold dishes, semi-finished salads and snacks

When evaluating cold dishes, semi-finished salads and snacks, special attention is paid to the appearance of the dish: the correct cutting of the main products, their texture (consistency).

Organoleptic evaluation of sweet dishes (desserts)

When evaluating sweet dishes, their group characteristics are taken into account. For jellied dishes, mousses and creams, first determine the surface condition, the appearance of the cut (break) and color. In addition, the ability to keep the shape in the finished dish is evaluated. Particular attention is paid to the texture (consistency). Then determine the smell and taste.When evaluating sweet hot dishes (soufflés, puddings, croutons, hot desserts, etc.), the appearance is first examined: the nature of the surface, the color and condition of the crust; mass on the cut (break): baked, no hardening. Then evaluate the smell and taste.

Organoleptic evaluation of flour culinary semi-finished products and products

When evaluating flour dishes, flour semi-finished products and culinary products, their appearance is examined (the nature of the surface of the dough, the color and condition of the crust of pancakes, pancakes, pies and other products, their shape), pay attention to the ratio of minced meat and dough, the quality of minced meat (its juiciness , degree of readiness, composition), and then determine the smell and taste.Organoleptic evaluation of flour confectionery and bakery semi-finished products and products

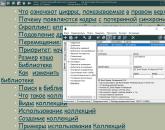

When characterizing the appearance of flour confectionery and bakery semi-finished products and products, attention is paid to the surface condition, its finish, color and condition of the crust, the absence of peeling of the crust from the crumb, the thickness and shape of the products. Then evaluate the state of the crumb: baked, no signs of non-mixing, the nature of porosity, elasticity, freshness, lack of hardening. After that, the quality of the finishing semi-finished products is evaluated according to the following characteristics: the state of the cream mass, lipstick, jelly, glaze, their splendor, plasticity. Next, evaluate the smell and taste of the product as a whole.book title open close

Product quality as a socio-economic category. Basic concepts, terms and definitions in the field of quality

Properties and indicators of product quality, their characteristics

Methods for determining product quality indicators

Formation of product quality

Production quality control of public catering products Organoleptic analysis of product quality

Terminology of organoleptic characteristics

Methodology for organoleptic quality assessment

Organoleptic evaluation of the quality of certain types of public catering products of mass production

Methods for studying the quality of public catering products, their characteristics

The procedure for sampling for laboratory research of the quality of public catering products

Physical and chemical methods of quality control of culinary products

- Determination of the nutritional value of catering products

- Determination of sugars in catering products

- Determination of starch in catering products

- Determination of alcohol in catering products

- Determination of table salt in catering products

- Determination of total acidity and alkalinity of catering products

- Determination of vitamin C content

- Determination of egg content

Organoleptic assessment of the quality of semi-finished products is carried out by appearance, color, smell; culinary products and dishes - in appearance, color, smell, texture, taste.

Finished semi-finished product - industrial products that have undergone subsequent processing.

Ready vegetables should be soft, but not deformed.

Ready vegetables must be the correct shape, the same size; soft texture; color characteristic of vegetables; the smell of burnt milk and vegetables is not allowed; may be partially boiled.

The finished semi-finished product from mushrooms is light brown in appearance with a pleasant "mushroom" smell and taste.

Organization of the processes of preparation and preparation of semi-finished products from vegetables and mushrooms, for complex dishes

Semi-finished products from vegetables and fruits are products prepared for thermal cooking, which have previously undergone mechanical and hydromechanical cooking (in some cases, both thermal and chemical).

Some semi-finished products from vegetables are produced centrally on large enterprises public catering or in specialized shops of fruit and vegetable bases for the supply of these semi-finished products to smaller enterprises (pre-cooking).

In addition, vegetable semi-finished products produced by the food industry are used in public catering.

Characteristics of raw materials. For the preparation of culinary products at public catering establishments, almost all known vegetables, fruits and berries are used, which are most often supplied fresh, as well as dried, pickled, salted, canned in jars and frozen. Vegetables and fruits used for the production of semi-finished products must meet the quality requirements of the current GOSTs, OSTs and PCT.

During the mechanical culinary processing of vegetables and fruits, their nutritional value, color, and sometimes taste, aroma and texture change. The degree of certain changes depends on the technological properties of raw materials and the processing modes used.

Technological properties of vegetables and fruits are determined mainly by the composition and content of nutrients(proteins, fats, carbohydrates, minerals, etc.) and structural features of their tissues.

Semi-finished products from potatoes, vegetables and mushrooms are products that have previously undergone mechanical, and in some cases, thermal cooking. At catering establishments working on raw materials, semi-finished products from potatoes, vegetables and mushrooms are prepared immediately before thermal cooking.

According to the type of vegetables, semi-finished products are divided into the following groups: semi-finished products from potatoes, root crops, cabbage vegetables, onions, fruits (tomatoes, pumpkin, legumes and cereals), salad, spinach and dessert vegetables, semi-finished products from mushrooms. In addition, they are divided into two large groups according to the processing method: semi-finished products in the form of raw peeled vegetables and mushrooms and semi-finished products that have also undergone thermal processing after mechanical cooking.

Semi-finished products in the form of raw peeled and chopped vegetables and mushrooms

The technological scheme for the production of semi-finished products in the form of raw peeled and chopped vegetables and mushrooms consists of sorting raw materials, washing, cleaning and cutting.

When sorting, rotten, beaten or sprouted specimens, foreign impurities are removed, and vegetables are distributed according to size, degree of maturity and their suitability for the preparation of certain culinary products.

Vegetables are washed to remove soil and sand residues from their surface, as well as to reduce contamination by microorganisms. Washed vegetables are semi-finished products intended for further thermal cooking unpeeled.

When cleaning vegetables, parts with reduced nutritional value are removed. Peeled vegetables are left whole or cut into pieces of various shapes, depending on their subsequent culinary use.

Popular

- Photo Print Pilot - print photos at home

- Epson Easy Photo Print - photo printing application

- How to behave in a job interview

- What is the difference between a supermarket and a hypermarket?

- Feathered evil: what happens in the nest where the cuckoo threw her egg

- Eagle owls and owls How to determine the sex of a long-eared owl

- What year did the Internet appear

- Owl as a pet How to distinguish the gender of an owl

- Birds of the Moscow Region (photo and description): large predators and small birds A bird that makes different sounds

- The Board of Directors of the PIK group of companies re-elected the board of the company Aleksey Kozlov Pik